DyeMansion develops precision colour system for 3D-printed eyewear

Eyewear manufacturers are embracing additive manufacturing, also known as 3D printing, to meet rising demand for personalised, lightweight and sustainable products. This shift enables greater design freedom and supports sustainability goals. However, maintaining high colour accuracy in 3D-printed frames remains a key challenge.

By 2032, the 3D-printed eyewear market is expected to nearly quadruple, becoming one of additive manufacturing’s fastest-growing segments. According to Dataintelo, the market will reach USD 3.49–4.8 billion by 2031–2032, compared to USD 1.2–1.63 billion in 2023–2024. Among its benefits, the advanced manufacturing process enables the reshoring of production, shortening lead times for new fashion collections and optimising supply chains through on-demand production and reduced inventory.

Consistency in part quality is a major hurdle for additive manufacturing, highlighted by 47% respondents in the survey by PostProcess. To address this, DyeMansion launched the Neptun project to deliver advanced calibration and process control capabilities.

Reproducibility at high quality at scale is one of the core capabilities of DyeMansion colouring systems. We enable manufacturers to deliver on demanding requirements with consistent quality throughout multiple production lines.

Mirko Bahrenberg, Head of Product Development at DyeMansion

Bringing high precision to colour calibration

DyeMansion, a Munich-based SME, specialises in post-processing solutions for industrial polymer 3D printing. Their print-to-product solution transforms raw printed parts into high-value products. The Neptun project, funded as part of the EIT Manufacturing Empowering SMEs Call 2023, was launched in collaboration with end-user Additive Scale, focused on scaling additive manufacturing for eyewear.

The project started with a challenge: how to achieve the repetitive colouring of 3D-printed eyewear frames at scale? Multiple factors affect the outcome: from sourcing raw materials (dyes), quality-enhancing customised recipes and industrial water treatment, to machine parameters and process adjustments.

DyeMansion’s advanced colouring technology uses their DM60 colouring system combined with a water filtration unit that removes minerals and salts, ensuring consistent and high-quality dyeing of 3D-printed frames. The system supplies desalinated water (purified water with salts and minerals removed) to ensure stable dyeing conditions. Within the process, colour dyes from cartridges are dissolved under precisely controlled temperature and pressure, ensuring consistent, high-quality finishes.

DyeMansion’s DM60 colouring system. Copyright (c) DyeMansion

Today, a high level of quality can be achieved with a lot of manual adaptations and testing cycles. But DyeMansion was looking for an approach that would allow users to replicate the same colour throughout multiple production lines and locations worldwide.

Scaling industrial production

The Neptun project tackled this in four stages. First, the team studied how water quality —specifically salts, metals and organic compounds — affects colour stability. They focused on anionic components, such as nitrate, sulphate, chloride and organic pollutants, taking into consideration that the amount varies per region and/or city. Next, they adjusted processes and optimised dye usage. After months of lab testing, the improved system was implemented at Additive Scale’s production site.

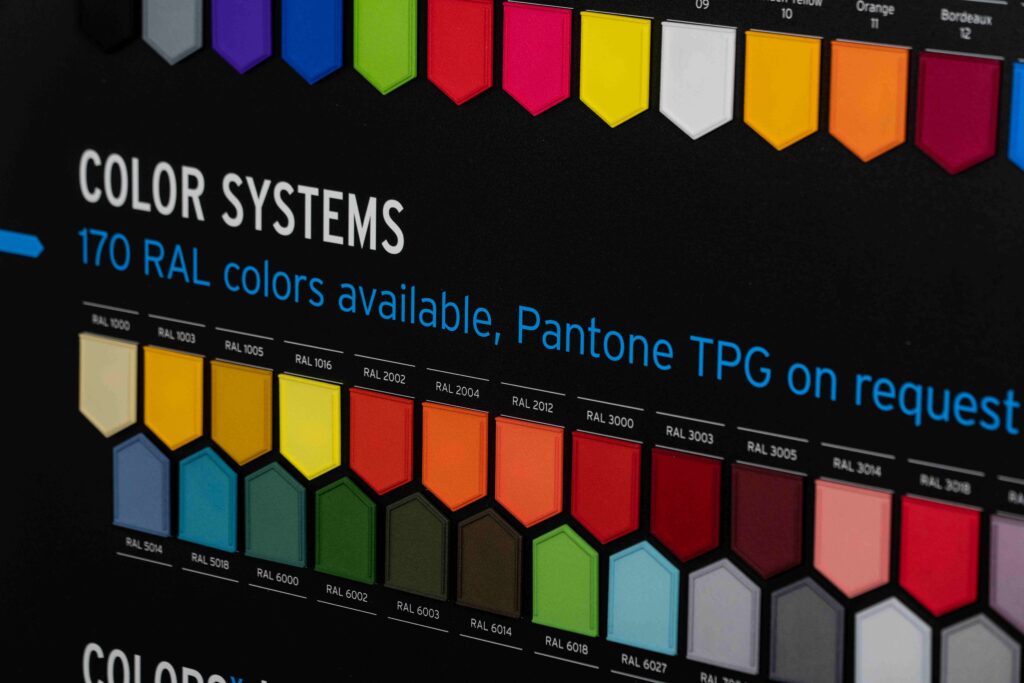

DyeMansion’s colour wall. Copyright (c) DyeMansion

Building on the proven DM60 system, new calibration modules introduced precise volumetric and thermal controls. The volumetric system maintains exact water dosing during each cycle to eliminate dilution errors, while thermal calibration ensures real-time temperature accuracy to prevent shade deviations. An “Expert Access” software module lets operators fine-tune parameters across machines and production sites, achieving consistent results.

Innovation beyond the aesthetics

The improvements go beyond aesthetics. By stabilising the dyeing process, DyeMansion enables eyewear producers to scale 3D printing operations without increasing scrap or compromising finish quality. The enhanced calibration system also reduces water and chemical use, contributing to more sustainable production lines.

3D-printed parts that have been colour-finished using DyeMansion’s technology. Copyright (c) DyeMansion

Now the company seeks to implement the solution further for customers working at scale with DyeMansion colouring technologies. Building on the experience of the highly demanding eyewear industry for exceptional reproducible colouring quality, the team is transferring the learnings and technical solutions to other industry sectors like orthosis and prosthesis, as well as automotive, which are at the edge of producing 3D-printed parts at scale.

In a rapidly evolving industry, achieving industrial-scale colour precision with DyeMansion’s solution is key to unlocking mass adoption of 3D-printed eyewear.

Transform your factory with 3D printing

Discover solutions for additive manufacturing with DyeMansion!