fleXstructures Italia proves ergonomic innovation is not a luxury

In today’s evolving industrial landscape, ergonomic risk remains a persistent and pressing challenge, particularly for sectors that depend heavily on manual and repetitive tasks. Despite advances in automation, many traditional manufacturing industries — where manual work is a symbol of quality and uniqueness — continue to expose their workforce to musculoskeletal risks. The risks come from poorly designed workstations, static postures and physically demanding routines.

Manuela Vargas Gonzalez, Senior Engineer at fleXstructures Italia, explains: “In sectors such as textiles, manual activities are still often carried out using outdated workstation designs, with limited inclusivity and few accessible ergonomic assessment tools, challenges that SMEs frequently struggle to overcome.”

To address this gap, fleXstructures Italia deployed IPS IMMA (Intelligently Moving MAnikin) — a Digital Human Modelling (DHM) solution that enables data-driven ergonomic and assembly validation directly within 3D CAD environments. By simulating the real activity with manikins representing the company’s actual team, IPS IMMA allows manufacturers to design safer and more efficient workstations early in the design process, bridging advanced digital technologies with underserved segments of the manufacturing ecosystem.

Through fleXstructures Italia, we demonstrated how advanced DHM can transform ergonomics from a reactive corrective measure into a proactive design driver. By actively involving workers and supervisors and complementing technical solutions with visual, video-based training, the project delivers measurable improvements in worker well-being and productivity, while enabling sustainable adoption and setting a new benchmark for ergonomic innovation in the industry.

Manuela Vargas Gonzalez, Senior Engineer at fleXstructures Italia

Why traditional approaches fall short

Manufacturers and product developers often struggle to ensure ergonomic viability and assembly feasibility early in the design phase. As a result, risks are identified too late, leading to costly redesigns, safety issues and suboptimal workstation layouts.

Conventional ergonomic assessments lack the precision, scalability and flexibility required to evaluate diverse worker populations and complex manual tasks within digital environments. This gap is particularly acute for SMEs, which often lack in-house expertise in ergonomics or digital transformation.

Enabling early, data-driven ergonomic validation for SMEs

fleXstructures Italia, an SME based in Turin, develops and distributes the IPS Tools software suite, supporting the design and optimisation of flexible components (IPS Cable), human digital modelling for process and ergonomic optimisation (IPS IMMA), robot process optimisation (IPS Robotics) and the simulation of complex surface treatment processes (IPS Virtual Paint, Sealing and Spray). In 2023, fleXstructures joined the EIT Manufacturing Empowering SMEs Call with the Humanify project.

IPS IMMA simulates realistic human movements across a full population range, allowing companies to evaluate posture, reachability, task feasibility and ergonomic risk before anything is built. This enables safer and more efficient workstation design, reduces late-stage changes and accelerates time to production.

With the support of EIT Manufacturing’s Empowering SMEs funding, fleXstructures Italia was able to advance this solution beyond conventional ergonomic assessment. The funding enabled the validation of this approach in real industrial contexts, particularly in industries where ergonomic evaluations had traditionally been performed using conventional methods.

Valerio Cibrario, Director of fleXstructures Italia

Cibrario explains: “By supporting a participatory methodology involving workers and supervisors, as well as the development of accessible, video-based training materials, EIT Manufacturing helped accelerate the adoption of proactive, data-driven ergonomic design, delivering tangible improvements in worker well-being, productivity and long-term sustainability for SMEs.”

Delivering a digital leap for ergonomic innovation

The project set out to demonstrate that an ergonomic improvement framework can be not only scientifically rigorous and technologically sound but also practical, scalable and financially accessible to SMEs — especially those with limited internal expertise in digital transformation or workplace design.

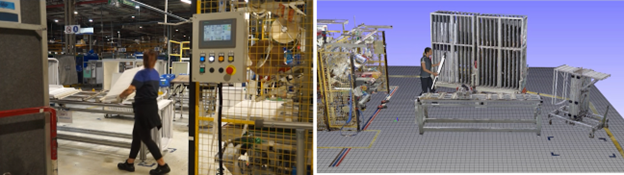

The project was implemented in collaboration with Fratelli Piacenza, a historic Italian textile manufacturer. The pilot served as a real-world test case, showing how advanced digital ergonomics tools can integrate into a traditional production environment without disrupting established processes.

fleXstructures Italia team at Fratelli Piacenza

Embedding ergonomics through digital simulation and collaboration

The project employed a dual approach: deploying the DHM platform IPS IMMA in a novel industrial context and simultaneously adopting a human-centric, participatory methodology.

Unlike traditional ergonomic interventions that rely on expert audits and static checklists, IPS IMMA enables dynamic simulation of worker activities, postures and forces using a family of manikins that reflects the full anthropometric variability — the full range of body sizes and proportions found among real workers — of the target population.

This included building a digital twin of the current scenario, a virtual optimised solution by co-creating improvements in close collaboration with workers and supervisors and developing intuitive training resources such as short educational video capsules for the workers. The method emphasised learning-by-doing, visual feedback and real-time ergonomics validation — making it a breakthrough in both technological and educational terms.

IPS IMMA in a real manufacturing environment. Copyright (c) fleXstructures Italia

A flexible, modular solution for real workplaces

Three workstations at Fratelli Piacenza were selected through on-site ergonomic assessments and interviews with personnel and supervisors. This ensured that real user needs guided the project’s priorities. The selected workstations were the following.

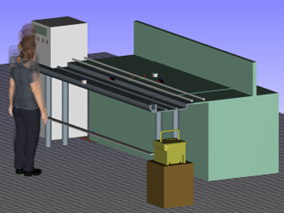

Fabric quality control is a fully manual process due to small production batches and high product customisation. Operators conduct visual inspection of the fabrics on a strongly illuminated, nearly vertical surface, performing repeated inspections that require sustaining visual attention.

Loom yarn knotting involves manually tying or repairing yarns directly on the loom. Due to the machinery’s geometry, operators work at varying heights and in constrained spaces, leading to awkward postures and increased physical strain.

Simulation of a loom yarn knotting workstation. Copyright (c) fleXstructures Italia

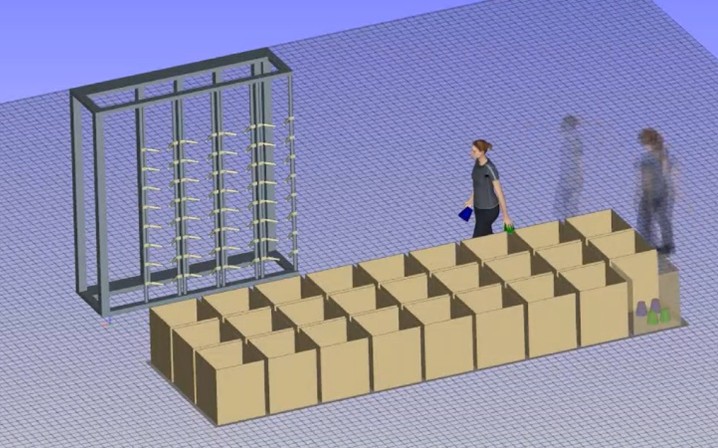

Spooling into the warping machine with thread knotting requires operators to manually place spools, guide threads through the machine and perform precise knotting. The primary challenge lies in the awkward postures due to the different positioning levels of the spools, while the repetitive and manual nature of the task makes it physically demanding.

Simulation of a spooling workstation. Copyright (c) fleXstructures Italia

The workstations were virtually reproduced, analysed and tested with multiple scenarios using IPS IMMA (As-Is). The identified physical improvements were implemented in two workstations, resulting in measurable reductions in ergonomic risk and improved worker well-being.

The project delivered a flexible, modular and field-tested ergonomic solution, which was seamlessly embedded into Fratelli Piacenza’s operations.

A scalable model for the future of work

This project shows how advanced digital tools, when thoughtfully applied, can transform not only processes but also people’s experience of work. The IPS IMMA-based solution delivered ergonomic improvements, cultural change and strategic business value within a single, unified initiative.

IPS IMMA is applicable across industries involving manual work, including automotive, railway, aerospace and defence, white goods, logistics, textile and fashion, chemical and pharmaceutical, food and beverage sectors.

The result is a replicable model for industries facing similar ergonomic and operational challenges — paving the way for a manufacturing future that is safer, smarter and more humane.