Layer by layer: Unfolding the state of additive manufacturing

“If you had EUR 1 million to invest in additive manufacturing, how would you spend it?” When you ask experts on additive manufacturing this question, their answers will give you an idea of the untapped potential of this young technology.

Industrial layer: The state of additive manufacturing

Additive manufacturing is moving beyond experimentation into industrial reality. Growing at around 20% annually, the technology is increasingly embedded in digital, data-driven production systems. Reflecting this breadth, it accounts for 27% of activities in the global advanced manufacturing industry, making it one of the leading technology areas, according to the Joint Research Centre (JRC).

Despite the misconceptions of “just prototyping”, a low-complexity technology, or a process where any design can be printed without constraints, additive manufacturing relies on advanced materials science, mechanics, software and systems engineering working in harmony — making it one of the most interdisciplinary manufacturing technologies in use today.

This technology has attracted sustained interest from industry, researchers and consumers due to the range of advantages it offers. These include design freedom for complex geometries, rapid prototyping and the ability to enable small- to large-scale customisation.

At the same time, lightweight structures and improved material efficiency can help reduce waste and energy use, contributing to cost savings across the value chain.

A Fraunhofer survey shows that, in the next five years, companies will prioritise small-scale production (81%), after-sales and spare parts (63%), and pre-series production (56%). Over a 5–10-year horizon, the focus shifts towards serial production (81%) and mass customisation (63% compared to 44%), signalling a clear move toward industrial-scale deployment.

What are the opportunities for additive manufacturing already being explored in Europe and key bottlenecks for adoption? Here we unfold — layer by layer — insights from AIMEN Technology Center, EU-funded project ORGANIC, Beespenser startup and Kilometro Rosso.

Digital layer: Additive as a digital manufacturing platform

Additive manufacturing has evolved beyond a standalone production method into a digital manufacturing platform. Its integration with artificial intelligence (AI), data-driven design, digital twins and closed-loop control systems is reshaping how parts are designed, validated and produced. Rather than focusing on individual machines, industrial value increasingly lies in how additive manufacturing systems are embedded within digital production environments.

Large-scale additive manufacturing (LFAM) illustrates this shift particularly clearly. At larger scales, process stability, design optimisation and cost control become inseparable from digital design, simulation and monitoring. LFAM is particularly valuable when only a limited number of components are needed, making it well-suited for industrial settings where proof-of-concept parts are required or where large production runs are unnecessary.

Ander Reizabal López-Para, Senior Researcher at AIMEN Technological Center, highlights that LFAM is becoming increasingly prominent in the mould-making industry. Thanks to its versatility and ability to adapt quickly to new production requirements, polymer-based LFAM moulds are enabling an entirely new class of tooling solutions.

By significantly reducing the cost and lead time, LFAM opens doors to accelerated product development, new application areas and even the revival of design concepts that were previously impractical or prohibitively expensive to realise using conventional mould-making methods.

Ander Reizabal López-Para, Senior Researcher at AIMEN Technological Center

Reizabal López-Para works on an EU-funded project ORGANIC, which addresses one of the main challenges of LFAM: technological immaturity. The project introduces a novel concept — gentelligence — inspired by natural evolution, enabling LFAM systems to autonomously generate manufacturing models adapted to both process requirements and technological constraints. By continuously monitoring its environment and operating conditions, LFAM can adapt both its physical configuration (phenotype) and its control mechanisms (genotype), thereby radically improving robustness, repeatability and industrial viability.

Wind turbine blades manufacturing

By combining LFAM with gentelligence, manufacturers can potentially reduce material consumption, lead times and production costs, while delivering high-performance, customised components. In ORGANIC, the gentelligence framework will be tested to exchange the traditional core materials of wind turbines blades against additively manufactured lattice structures made from bio-based materials.

Sustainability layer: Beyond assumptions

Additive manufacturing is often associated with sustainability benefits, yet it’s not a default setting. While the technology enables material efficiency, lightweight structures and functional integration, its environmental performance depends on design intent, material sourcing, energy use and end-of-life strategies.

“In the field of printed and dispenser-based additive manufacturing, sustainability is often assumed, but it is not inherent to the process itself”, highlights Yaren Özdemir, Co-Founder and CMO of Beespenser. “Additive manufacturing becomes sustainable only when materials, hardware and process design are developed together with a clear application logic.”

Özdemir explains that in printed electronics, material efficiency can be high, yet this advantage quickly diminishes if functional inks require hazardous solvents, excessive post-processing, or unstable deposition behaviour. A significant part of sustainability lies in how materials are formulated and handled, as well as in how precisely they can be dispensed and controlled during fabrication. Well-defined ink rheology (precisely controlled flow and solidification behaviour of the printing ink) and controlled deposition are essential to minimising waste and ensuring repeatable functional performance.

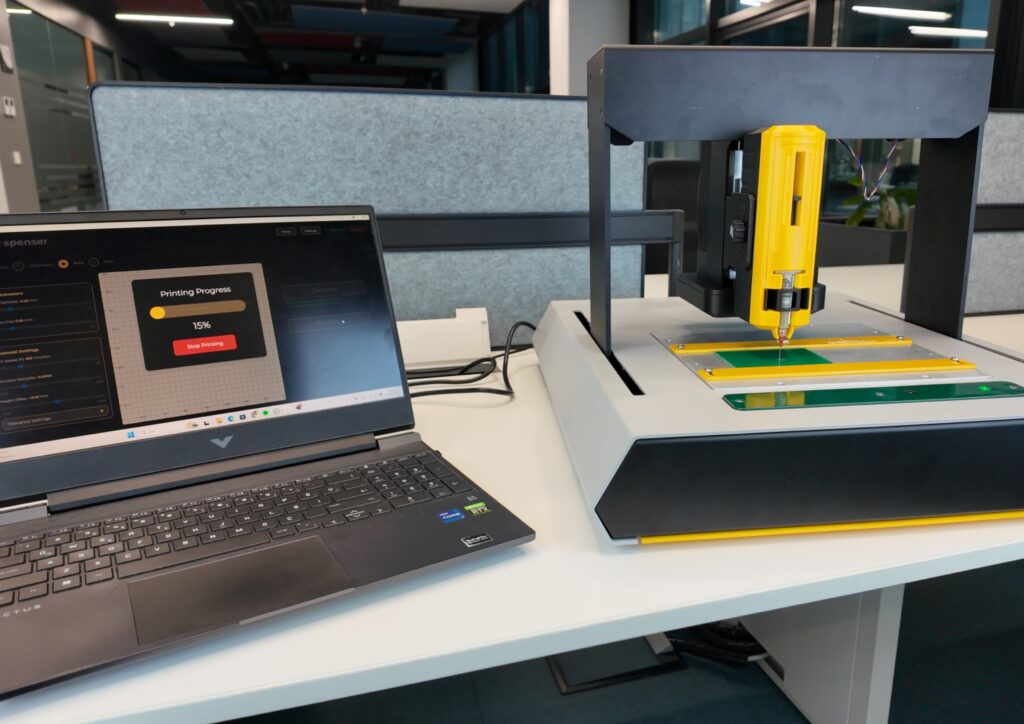

Monobee, a micro-dispenser system developed by Beespenser, enables additive manufacturing of viscous functional materials on both flexible and rigid substrates. Copyright (c) Beespenser

Looking ahead, Özdemir sees sustainability in additive manufacturing to be increasingly evaluated through measurable, system-level metrics rather than assumptions. In printed electronics, this means focusing on how efficiently function is delivered: fewer steps, lower material loss, reduced rework and tighter integration between ink chemistry and dispensing hardware. Sustainability, in this sense, becomes the result of process intelligence rather than process novelty.

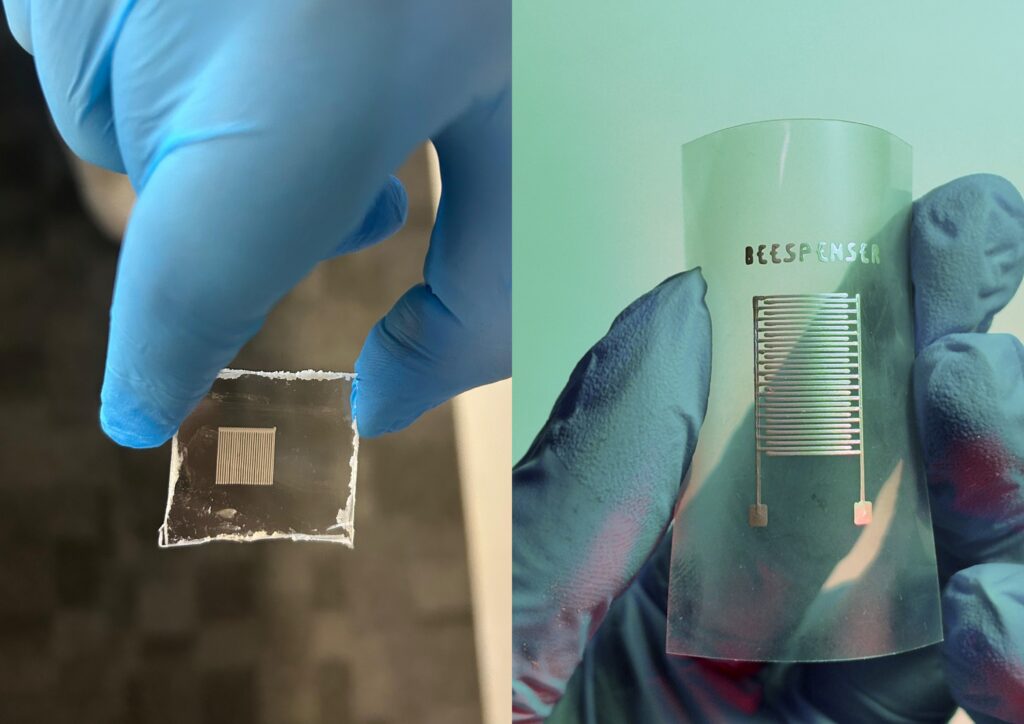

An example of 3D-printed functional electronic circuit, where conductive traces, interconnects and solder layers are built layer by layer, enabling fast transition from design to working device. Copyright (c) Beespenser

Perception layer: Additive is not a magical tool

I would like the industry to perceive additive manufacturing, particularly in printed electronics, not as a direct replacement for conventional manufacturing, but as a tool for enabling functions that are otherwise difficult or inefficient to produce.

Yaren Özdemir, Co-Founder and CMO of Beespenser

One common challenge when working with clients, shares Özdemir, is the expectation that additive manufacturing should immediately behave like a mature mass-production technology. In practice, its real strength lies in rapid functional iteration, where materials, designs and processes evolve together within the R&D environment. This is especially true in printed electronics, where performance depends not only on design geometry, but also on how materials are deposited and cured in real conditions.

Ultimately, additive manufacturing should be understood as a way to bring manufacturing logic closer to research and development. By allowing teams to move seamlessly from material formulation to functional electronic output, it lowers the barrier between experimentation and validation. When positioned this way, additive manufacturing becomes a strategic enabler of innovation rather than an alternative to existing production methods, concludes Özdemir.

Biosensor arrays and supercapacitor structures fabricated on glass and PET substrates using the Monobee system. Copyright (c) Beespenser

As additive manufacturing is moving towards industrial scale, skills — not machines — are the primary bottleneck. Scaling requires targeted skills development, especially in design for additive manufacturing (DfAM), AI and data literacy, and systems thinking. No single discipline is sufficient. Employers increasingly value engineers who can work across domains and collaborate with multidisciplinary teams.

Federico Molteni, Additive Manufacturing Specialist at Lisa Tech lab, Kilometro Rosso, shares that the world of additive technologies means that every day you might be working on something completely different. Applications range from conformal cooling in the injection moulding sector to topology optimisation in aerospace and motorsport.

There are two main skills that are fundamental to scale in any sector of the additive manufacturing industry: material knowledge and willingness to experiment. The former is essential to know how and why to implement certain additive solutions and the latter is useful for exploring new ideas without the fear of failure.

Federico Molteni, Additive Manufacturing Specialist at Lisa Tech lab, Kilometro Rosso

Lisa Tech laboratory with EOS M290 machine. Copyright (c) Kilometro Rosso

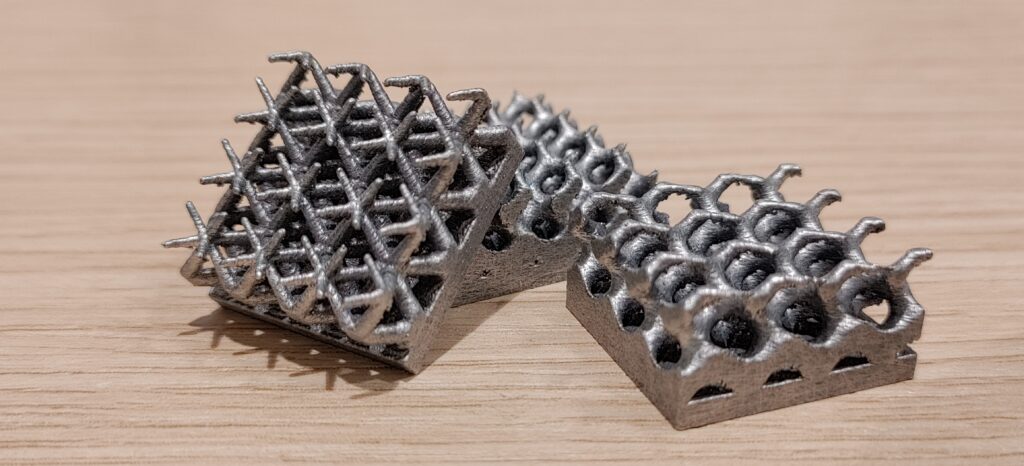

The work at Lisa Tech illustrates a broader industry pattern. Companies often need controlled environments to test and validate additive solutions before committing to major investments. Through European-funded initiatives such as the DIH-World project, the team collaborated with an industrial partner at Kilometro Rosso to redesign a conventional heat exchanger using additive manufacturing. By analysing, testing and producing aluminium prototypes, the team achieved performance improvements over the standard component.

Three different 3D-printed lattice heat exchangers. Copyright (c) Kilometro Rosso

The World Economic Forum (WEF) identifies adoption barriers across technological, organisational and ecosystem dimensions, among which the main challenges lie in the absence of clear adoption strategies, limited ability to identify value-adding use cases and persistent know-how gaps. Could the solution be the rise of internal champions? WEF sees so-called additive intrapreneurs as professionals who can promote the value and benefits of additive manufacturing within their organisation and translate technical potential into industrial reality.

Being a technology expert does not necessarily mean being able and willing to share your knowledge. However, innovation requires constant exchange of knowledge.

Chiara Bertazzoni, Public Funding Specialist at Kilometro Rosso

To facilitate it, Bertazzoni says that Kilometro Rosso invites students and professionals to visit Lisa Tech laboratory. The team also offers dedicated Additive Manufacturing I and II courses developed with INFINITY project partners on the EIT Manufacturing Academy. Together, these initiatives offer structured knowledge transfer for students, professionals and industry practitioners.

As additive manufacturing matures, the challenge is no longer access to technology, but the ability to build organisations that continuously share knowledge, develop talent and translate experimentation into industrial value.

Electronic board with 3D-printed heatsink. Copyright (c) Kilometro Rosso

The EUR 1 million answer

When asked where they would invest EUR 1 million, the above experts prioritised people, digital systems, materials and quality over hardware alone. Their perspective underscores a shared belief that additive manufacturing’s future will be defined less by machines and more by how effectively Europe builds the skills and ecosystems around them.

This edition of the industry insights is part of the AGORA Talks webinar ‘The future is additive – Advanced manufacturing with in-demand skills’, moderated by Yevgen Sakalo, Lifelong Learning Project Officer at EIT Manufacturing. To watch the webinar, please follow this link and request access if you are not yet a member of AGORA.