MaestroHub: Building the industrial data backbone manufacturers need to scale performance and deploy AI

Across manufacturing, digital ambition is high. Yet on the factory floor, execution often stalls. Machines, lines and plants generate vast amounts of data, but much of it remains fragmented, inconsistent or operationally unusable. The result is slower decision-making, limited cross-site visibility and digital initiatives that struggle to move beyond the pilot phase

MaestroHub, a Türkiye-based technology company, addresses this challenge head-on. It solves the problem of fragmented and unreliable factory data that slows decisions and blocks digitalisation at scale. It works with multi-site manufacturers that require a real-time, governed data layer to improve overall equipment effectiveness (OEE), reduce waste, enable AI and scale performance across machines, lines and plants.

From fragmented systems to a unified operational view

Most manufacturers operate with fragmented systems, inconsistent data structures and long integration cycles. Over time, this complexity has become a structural barrier to performance improvement. Studies and factory assessments consistently show that 20 – 30% of operational performance remains untapped, while more than 70% of available shopfloor data is never used to inform decisions.

MaestroHub tackles this issue by creating a unified, governed data layer that standardises information across machines, MES, PLCs and ERP systems, without requiring manufacturers to replace or disrupt existing infrastructure. The platform supports more than forty industrial protocols natively, allowing heterogeneous equipment to be connected quickly and non-disruptively.

By transforming raw machine signals into contextualised, decision-ready data in real time, the platform gives manufacturers a shared operational language across lines and sites. Deviations can be detected and addressed within minutes rather than hours, improving consistency and responsiveness across production environments.

Fragmented factory data remains a major barrier to digital progress because it prevents organisations from acting on a single, timely and consistent operational truth.

Yasir Tunçer, CEO of MaestroHub

Measurable impact on efficiency, waste and scalability

The impact of a unified industrial data backbone becomes visible at operational level. Manufacturers using MaestroHub achieve measurable improvements, including:

- Up to 25% reduction in downtime

- Around 20% less production waste

- ROI ranging from 2× to 10×, depending on scale and use case

With real-time visibility across lines and sites, the company enables deviations to be detected and corrected within minutes rather than hours. Rapid deployment and broad protocol coverage create a unified, AI-ready data foundation that improves decision quality, stabilises operations and supports consistent performance at scale.

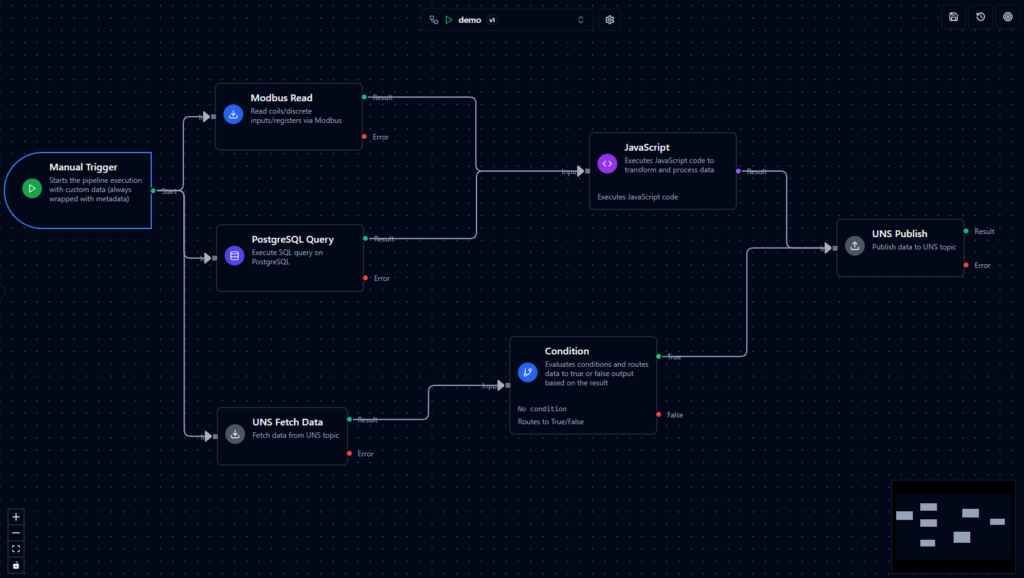

Example of the flow of executing a papeline with MaestroHub

Manufacturers move from isolated data to scalable performance gains by establishing a continuous, shared and traceable operational truth across the enterprise.

Yasir Tunçer, CEO of MaestroHub

Enabling digitalisation, sustainability and AI readiness

The platform supports digitalisation, automation and sustainability by providing governed real-time datasets needed for AI, energy optimisation and traceability. Its consistent data models allow manufacturers to track material flows, energy consumption and CO₂ emissions accurately, helping them operationalise ESG metrics and automate reporting.

This data foundation also supports circular economy practices, where reliable traceability and transparency are essential. As manufacturers prepare to deploy digital twins and AI agents, the need for standardised, trustworthy data becomes critical. MaestroHub positions itself as an Industrial DataOps layer built to support this next phase of industrial transformation.

How a MaestroHub dashboard looks like

Built from factory reality, not theory

The idea behind the company emerged after more than 40 factory readiness assessments revealed a recurring pattern: fragmented data was preventing real operational improvement. The company’s first major milestone came when a unified namespace deployment delivered measurable OEE and downtime gains within sixty days. This early validation confirmed the need for a scalable Industrial DataOps layer purpose-built for manufacturing.

The founding team brings deep roots in manufacturing, industrial digitalisation and distributed systems architecture. The founders previously led large-scale Industry 4.0 programmes and factory integrations across automotive, machinery and consumer goods. Their combined backgrounds in production engineering, OT/IT integration and cloud-native architecture directly shape MaestroHub into a platform built for real factories, fast rollout and multi-site governance.

Scaling across sites and markets

Today, MaestroHub is fully commercialised and deployed in enterprise manufacturing environments across automotive, appliances, chemicals and metals. The company supports pilots, multi-site rollouts and partner-led integrations, with a deployment model focused on fast time-to-value and repeatability.

It is currently expanding across Europe, Middle East and Africa (EMEA) with active multi-site deployments, while preparing for North America through integrator channels and ecosystem programs such as NVIDIA, AWS (Amazon Web Services) and regional manufacturing clusters. Its near-term roadmap includes advanced governance modules, expanded industrial protocol coverage and AI-ready data pipelines that allow factories to adopt analytics and automation with minimal integration effort.

The scaling approach follows a clear pattern: start with a contained 60-day pilot, standardise data through a unified namespace and roll out across lines and plants using reusable models, connectors and playbooks. This makes the MaestroHub platform particularly relevant for large manufacturers and portfolio-wide modernisation programmes.

A pragmatic role within the European manufacturing ecosystem

As part of its development, the company has engaged with the broader European manufacturing ecosystem. EIT Manufacturing has supported efforts to increase the company’s visibility and provided strategic mentoring, strengthening their multi-site data governance roadmap and industrial positioning. This contribution complemented MaestroHub’s focus on commercial deployment and helped validate its approach with manufacturers operating at scale.

MaestroHub’s trajectory reflects a broader shift underway in manufacturing: from isolated digital tools to shared, governed data infrastructures that underpin long-term competitiveness. As factories face rising cost pressure, sustainability targets and growing operational complexity, turning industrial data into a reliable and scalable asset is no longer optional. By providing a robust data backbone that works with existing systems and real factory conditions, the platform shows how efficiency gains, AI adoption and more sustainable operations can move from ambition to operational reality on factory floors today.