In the digital race to modernise manufacturing, data is abundant, but rarely actionable. Spanish startup Muutech is solving that disconnect with a promise: to give manufacturers “your plant at a glance.” Their low-code, real-time monitoring platform is helping manufacturing teams replace paper reports, clunky Excel files, and isolated systems with unified, actionable intelligence, right from the shop floor.

Founded in Vigo by telecommunications engineers Víctor Calvo (CEO) and Fernando Fernández-Valdés (CTO), alongside industrial expert Óscar González, Muutech bridges the traditional divide between IT and operational technology (OT). Their platform brings together expertise in IT, cybersecurity and industrial systems to solve a fast-growing challenge: bridging the gap between the data industries collect and the decisions they need to make.

Solving fragmentation with simplicity

Industrial environments are under increasing pressure to become data-driven, but most still rely on manual reporting and disjointed systems like MES, ERP, sensors, and spreadsheets. These sources rarely talk to each other, making it difficult to gain a clear, real-time picture of operations.

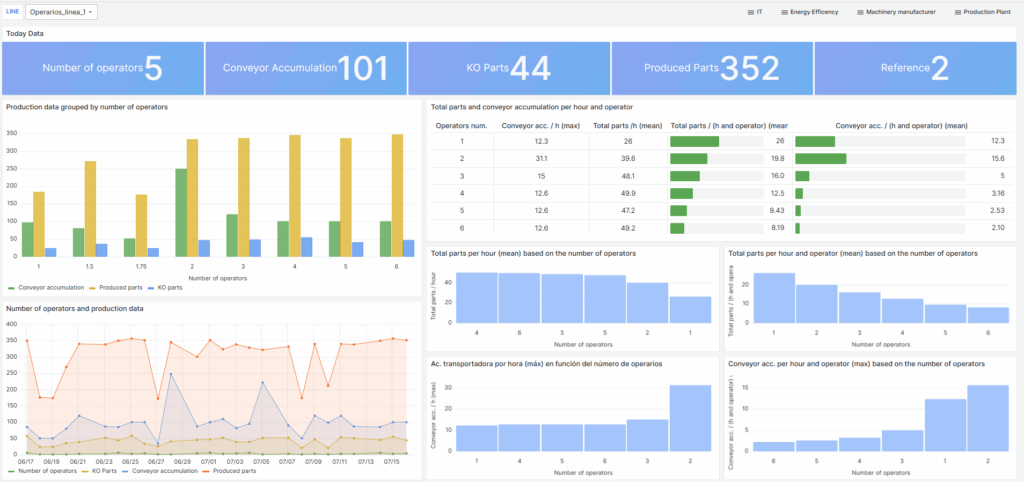

Muutech’s solution? A low-code, plug-and-play platform that connects any machine or system, then visualises, analyses, and contextualises the data in real time. Their Monitoring as a Service model combines technology and expert support in a single subscription, eliminating the need for costly consulting or in-house tech teams.

We solve a growing problem in industry: data is either not collected, collected manually on paper or Excel, underused, or scattered across disconnected systems. This makes real-time decision-making difficult. Unlike traditional IoT platforms, our clients don’t need deep technical knowledge or long development cycles. We deliver fast, tailored, and future-proof monitoring, fully integrated with analytics, AI, and real-time dashboards from day one.

Víctor J. Calvo, CEO and Managing Director

Tangible results, measurable impact

In sectors like automotive, metal, and food processing, where uptime and efficiency are everything, Muutech’s platform is already making a difference. On average, customers report:

- 25% reduction in monitoring and supervision time, thanks to automated alerts and centralised dashboards.

- Up to 20% improvements in productivity, by giving teams real-time data access without waiting on post-shift reports.

- For instance, a plastics manufacturer saved the equivalent of one full operator’s time per week, freeing up valuable capacity for production.

By automating data collection and surfacing actionable insights, Muutech is helping manufacturers detect problems earlier, reduce downtime, and optimise machine usage.

Digitalisation meets sustainability

Muutech’s impact goes beyond productivity. Their platform actively supports predictive maintenance, energy efficiency, and reduced waste, contributing directly to industrial sustainability goals.

Our platform replaces manual data collection with real-time monitoring, enabling decisions that optimise resources and reduce environmental impact. It’s a practical way to support circular economy strategies, doing more with fewer resources.

Víctor J. Calvo, CEO and Managing Director

As manufacturers face mounting regulatory pressure and ESG targets, solutions like Muutech’s are becoming not just helpful, but essential.

From local pilots to international expansion

The startup’s journey began with a clear pain point: the disconnect between IT and OT in industrial settings. Early validation came through the Business Factory Auto programme, where Muutech demonstrated real-world impact in demanding production environments. One milestone was deploying their platform across 15 machines at a high-volume metal components plant, proving their solution could scale and deliver results fast.

Today, Muutech is fully commercialised, with active clients in Spain, Portugal, Central Europe, and Latin America. Their sights are now set on expanding into Italy, Czechia, Slovakia, Poland, Romania, and Slovenia, regions with strong industrial heritage and rising demand for smart factory solutions.

Backed by ecosystem support

To scale effectively across Europe, Muutech has turned to EIT Manufacturing for strategic backing. As part of its internationalisation efforts, the team sees the pan-European network as key to gaining visibility, finding industrial partners, and tapping into collaborative innovation.

We believe EIT Manufacturing can help us scale our solution in new markets, through strategic connections, credibility, and access to real-world projects.

Víctor J. Calvo, CEO and Managing Director

A vision for industry that’s human-first

As industries digitalise, Muutech wants to ensure that technology empowers, not overwhelms, operators and managers. Their vision is clear: to democratise access to real-time industrial data, so that companies of any size can make better, faster decisions.

Data alone doesn’t drive performance. Empowered people do. When real-time analytics reaches everyone on the shop floor, data stops being noise and becomes a superpower. It’s what enables teams to act faster, smarter, and more sustainably.

Víctor J. Calvo, CEO and Managing Director

With a smart, user-friendly platform and a growing track record of impact, Muutech is showing how digital transformation can be accessible, sustainable, and deeply human, right from the factory floor.