STILFOLD: The origami-inspired manufacturing revolution that’s turning heads in Europe

Discover STILFOLD

As Jonas Nyvang, CEO of STILFOLD, held the EIT Manufacturing Innovation Award 2025 in one hand and raised his hand to the clapping audience with his other, he was clearly overjoyed. “Winning this award is giving me goosebumps,” he told the audience. “And to think, it all started with a piece of paper.”

STILFOLD’s innovation lies in what it calls “industrial origami”—a radical new approach to manufacturing that uses robotic folding of sheet metal to form strong, lightweight structures without the need for traditional tools like moulds, dies, or stamping machines.

At its core, the process draws inspiration from origami, blending material science, industrial design and robotics into what Nyvang describes as a “tool-less, flexible production system.”

We believe the future of European manufacturing is not about building bigger factories. It’s about being smarter – doing more with less. Competing on value, not price.

Jonas Nyvang, CEO of STILFOLD

From paper to product

The idea may have started as a metaphorical paper fold, but it quickly evolved into a tangible proof of concept. STILFOLD’s team developed an electric scooter chassis using their folding technique, dramatically simplifying the structure. The results were staggering: they reduced the number of parts from 159 to just 26, cut the weight from 55 kg to 12 kg and consolidated more than 20 materials into a single one.

“This wasn’t just about building a product,” said Nyvang. “It was about showing what’s possible through real-world use, not flashy features.”

Since then, the company has developed more than 20 pilot projects and is now heading into production with a major player in off-highway vehicles.

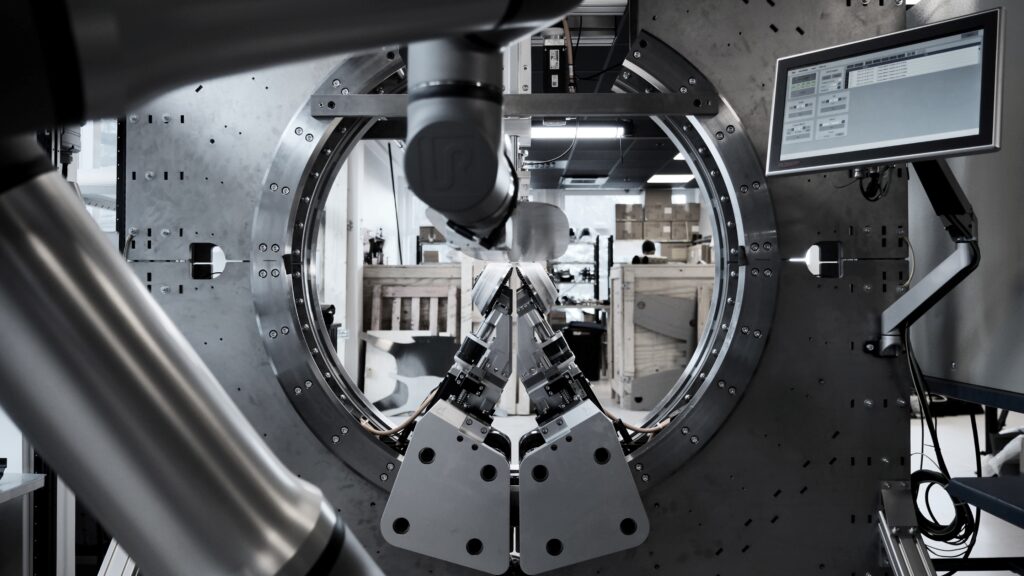

STILFOLD folding cell

Built for circularity and flexibility for a resilient Europe

STILFOLD’s manufacturing system is designed with circularity and resilience at its heart. Components can be flat-packed and folded on site, enabling local, modular assembly. This approach reduces logistics, material waste and environmental impact. “We’re building a system for the future, where products can be designed to be repaired, remanufactured and even unfolded,” said Nyvang. “It’s a mindset shift for the entire industry.”

Beyond the hardware, the company is investing heavily in software. Using AI and digital twin to speed up the time to market, STILFOLD helps manufacturers simulate and optimise every fold. “We’ve already invested over EUR 10 million into the development,” Nyvang noted.

STILFOLD’s model is built for scalability. The company offers a freemium and licensing model that will integrate into existing Computer-Aided Design (CAD) systems such as SolidWorks and Siemens NX, alongside a proprietary Computer-Aided Manufacturing (CAM) module that enables plug-and-play adoption by certified local integrators.

“We’re rolling this out with a programme to train 250 engineers and designers this autumn,” said Nyvang. “It’s pay-per-use – accessible, adaptable and ready to scale.”

And when it comes to mass production, STILFOLD’s flexible system is already delivering impressive results. “We’re hitting 10 meters folding per minute,” he said. “It’s fast. We’re not at million-unit batch levels yet, but we can go from design to prototype to production in days, not months. That’s the power of flexibility.”

Shaping a new era

Nyvang believes Europe is at a turning point. The pressures of climate change, supply chain disruptions and economic volatility are forcing manufacturing to evolve. “We’re living in extraordinary times,” he said. “And we’ll remember this era because it’s when everything started to shift. We’re building the tools for a smarter, more sustainable future – and we’re just getting started.”

With its groundbreaking technology, visionary leadership and now an EIT Manufacturing Innovation Award 2025 under its belt, STILFOLD is unfolding the future of European industry.

Folding the future with industrial origami

Discover origami engineering and tool-less manufacturing with STILFOLD