YK-Robotics democratises access to advanced robotics

Manufacturers across Europe are facing a growing shortage of workers willing to perform repetitive, physically demanding and labour-intensive tasks, according to the European Employment Services (EURES) and the European Centre for the Development of Vocational Training (Cedefop) reports. This challenge is particularly acute in industries such as metalworking, where productivity, quality and flexibility are critical to competitiveness. While robotic automation offers a clear solution, the complexity, cost and specialist expertise required to deploy advanced robotic systems continue to limit widespread adoption.

As production environments become more dynamic and product lifecycles shorter, manufacturers increasingly require flexible automation systems that can be reconfigured quickly without extensive support from system integrators. However, traditional robotic solutions remain largely rigid, hardware-specific and dependent on expert-level programming, creating a significant barrier for SMEs and high-mix, low-volume operations.

YK-Robotics identified an opportunity to simplify the entire lifecycle of robotic systems — from virtual cell design and task configuration to deployment, operation and maintenance — with its all-in-one software. Their system combines flexibility, intelligence and accessibility to empower both experts and non-experts to deploy and manage robotic cells efficiently, regardless of the hardware ecosystem.

YK-Robotics team

Simplifying robotics through software intelligence

YK-Robotics is a Florence-based SME that facilitates the adoption of advanced robotics in businesses of all sizes by providing robotic applications that can be seamlessly configured, programmed and controlled. The team joined the EIT Manufacturing Empowering SMEs Call 2023 with the YK-Platform project. Built on ROS2 (Robot Operating System), the YK-Platform integrates state-of-the-art open-source motion planning technologies to enable autonomous, collision-free trajectory generation and optimised robot motion.

Its brand-agnostic software minimises dependency on system integrators and streamlines configuration, programming and maintenance — enabling manufacturers to deploy and scale automation faster.

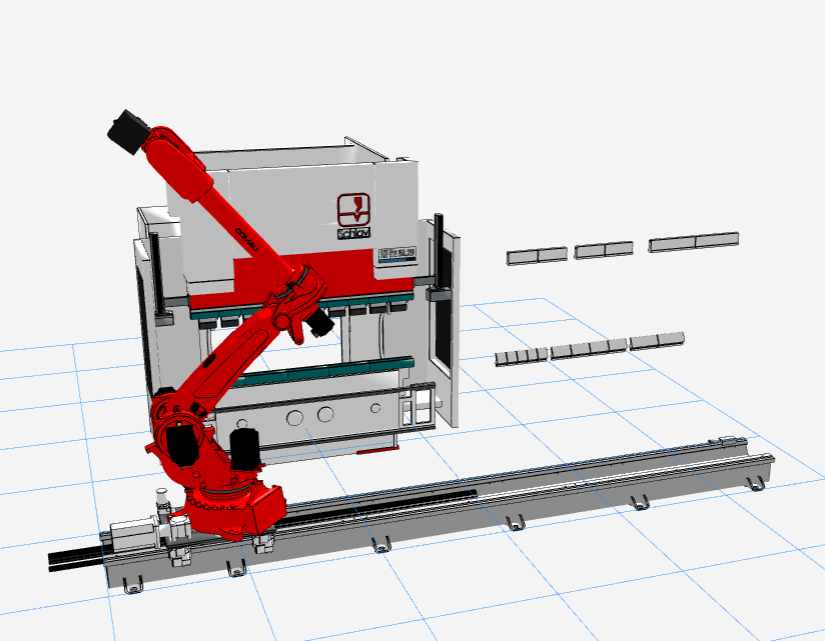

YK-Robotics platform allows to simulate processes, configure layouts from the element library, import 3D layouts and run feasibility checks. Copyright (c) YK-Robotics

During the project, the team conducted extensive comparative evaluations of multiple motion planning algorithms, analysing convergence and execution speed, robustness and performance under simulated real-world conditions. A test-driven development approach, covering more than 100,000 test cases, was applied to validate system reliability, including support for linear axes and multiple robot brands.

To accelerate development cycles and improve software quality, the team used AI-based development assistants such as GitHub Copilot and ChatGPT for code generation and test coverage, enabling faster iteration and more resilient system behaviour.

Talking about the project, Joan Ortega Alcaide, CEO and Co-Founder of YK-Robotics, states that EIT Manufacturing’s funding was the catalyst that enabled a mid-sized industrial company to take the risk of exploring a startup solution, while simultaneously giving YK-Robotics the opportunity to stress-test our software in real industrial scenarios. Ortega Alcaide highlights further: “This allowed us to enter a high-potential but previously unexplored market, where real problems emerged, were addressed, and directly contributed to improving our software.”

In robotics, a small but critical portion of development and validation must be performed on physical systems for any software solution to be truly effective. Reproducing such realistic conditions is often expensive and time-consuming. Thanks to the support of EIT Manufacturing and Schiavi Macchine International, we were able to access these ideal conditions and significantly accelerate the maturation of our solution.

Joan Ortega Alcaide, CEO and Co-Founder of YK-Robotics

Schiavi Macchine International is one of the YK-Robotics manufacturing partners. Elia Zinetti, CEO of Schiavi Macchine International, explains: “We develop bending machines, many of which are loaded by robots, across a wide variety of cell layouts and applications. Our systems manipulate and bend a large variety of unknown parts, and our clients require the ability to rapidly change the part being handled while ensuring collision-free operation.

Thanks to YK-Robotics, our operators and clients can autonomously generate new, safe production programmes, guaranteeing collision-free execution. This provides the flexibility the market demands while significantly reducing operational risk.

Elia Zinetti, CEO of Schiavi Macchine International

From HMI-centric to API-first robotics

One of the most significant outcomes of the project was the transformation of the YK-Platform into a modular solution driven by application programming interfaces (APIs). This architectural upgrade makes the platform natively interoperable with external applications and customised user interfaces, removing dependence on traditional graphical Human-Machine Interfaces (HMIs).

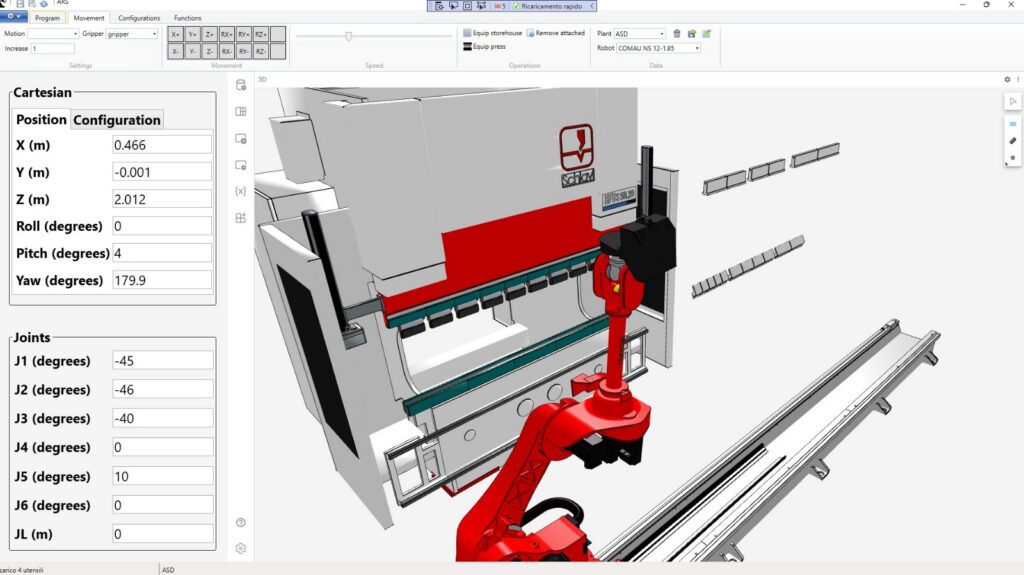

Over 30 robust APIs have been developed to support seamless configuration of robotic work cells that let users model and test the entire robotic cell layout in software before physical build-out, as well as trajectory planning and motion control. These new capabilities allow third-party integrators and machine builders to embed the platform within their own ecosystems effortlessly.

This API-first architecture enables machine builders and system integrators to embed YK-Platform directly into their own digital ecosystems while maintaining full control over user experience and workflows. In parallel, comprehensive deployment documentation, training materials and onboarding processes were delivered to support scalable market adoption, addressing both traditional HMI-based and API-based license offerings.

YK-Platform enables switching between any robotic arm without dependency, operates through a no-code interface and seamlessly integrates every component of a robotic cell. Copyright (c) YK-Robotics

Enabling flexible, human-centric automation

For end users, the impact is immediate. Manufacturers can autonomously generate complex robotic scenes, configure tasks and retrieve optimised, collision-free motion plans with minimal expertise. System updates, layout changes and maintenance operations can be managed quickly, making the platform particularly suitable for dynamic environments such as metal bending, machine tending, assembly and pick-and-place applications.

Key target sectors include food and beverage, where high product variability demands flexible, easy-to-configure automation. In wood and furniture manufacturing, the platform enables efficient handling of non-standardised parts with rapid adaptation to shifting production needs. Metalworking and machining benefit from optimising machine tending with reduced operator dependency and increased productivity. Pharmaceutical manufacturers gain cleanroom-compatible, precise handling tasks that can be quickly adapted to new packaging formats or regulations.

Across these sectors, the YK-Platform delivers the greatest value in environments that require frequent production changes or the handling of a diverse range of products within a single robotic cell.

Impact beyond technical innovation

The broader impact of this project extends well beyond technical innovation. The YK-Platform democratises access to advanced robotics by empowering a wider segment of the workforce to become active participants in modern manufacturing.

Adoption of this solution reduces reliance on hard-to-source manual labour, while providing a scalable automation pathway. In addition, optimised robot trajectories help reduce energy consumption and material waste, supporting more sustainable production practices.

Building the foundation for human-centric manufacturing

The YK-Platform represents a compelling response to both technical and societal challenges in manufacturing. By bridging the gap between robotics and usability, the YK-Platform has the potential to become a foundational technology in the next generation of flexible, intelligent and human-centric manufacturing systems.

As artificial intelligence (AI) technologies mature and large language models (LLMs) become more accessible, YK-Robotics is extending the platform with natural language interaction capabilities. The team has developed a set of AI agents, currently in beta testing, designed to operate on top of the YK-Platform’s existing functionalities. These agents can interpret operator requests, assign tasks to the appropriate specialised agent and support activities such as virtual robotic cell generation, robot programming, data exchange and human-machine interface creation.

By adding this layer of interaction, operators can describe what needs to be done using natural language, while the YK-Platform translates these inputs into executable actions. This approach further lowers the barrier to deploying advanced robotics and points towards a future where human–robot collaboration becomes more intuitive and accessible across manufacturing environments. The team is currently working on scaling the solution and is open to collaboration with investors and industrial partners.

Get started with robotics

Accelerate innovation and efficiency with YK-Robotics Platform!