Canonical Robots brings plastics recovery for the automotive industry

Plastics now rival steel as a structural material in modern vehicles. They make up 15% of the average car, which is around 150-200 kg, according to PlasticsEurope. Achieving a lightweight design for vehicles is crucial for reducing fuel consumption and carbon emissions. This is why plastics are used for automotive components, traditionally made from steel, for their lightweight, high-performance and lower cost.

Following the European Commission’s End-of-Life Vehicles Directive from 2023, reinforced by the Circular Economy Action Plan, component manufacturers need to incorporate at least 25% of recycled plastic into their products. However, they encounter significant challenges due to a shortage of suppliers capable of providing certified plastic with the required 95% purity. A study shows that less than 10% of auto shredders are equipped with plastic sorting technology (PST), mainly located in Western Europe.

“Reliable identification of visually similar plastics flowing at industrial speed remains a bottleneck for the recycling industry”, says Ignacio Secades, Sales & Partnerships at Canonical Robots. Manual sorting cannot reach the 95% purity, while existing optical machines struggle with additives, colours and throughputs. To address this critical gap, Spanish SME Canonical Robots developed the CIRPLASTIC solution, designed to classify various types of plastics. The deployment of this system will help close the compliance gap for European recycling plants and automotive moulders processing end-of-life vehicle plastics.

Robot-as-a-Service for recycling plants and automotive moulders

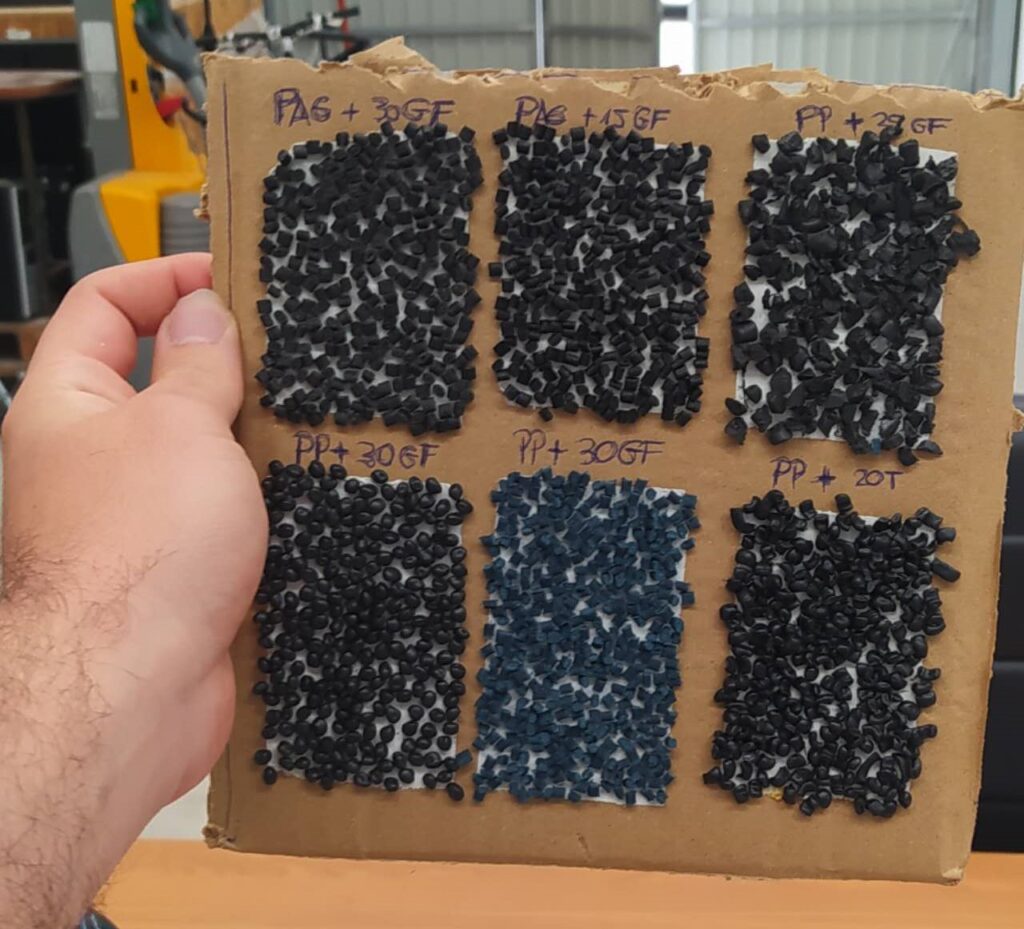

CIRPLASTIC’s core functionality revolves around hyperspectral imaging (HSI) technology in the 955-1700 nm wavelength range, integrated with sophisticated data processing techniques such as normalisation and the Savitzky-Golay filter. This approach allows for detailed recognition of various plastic types based on their spectral signatures, which is essential for automating the sorting process. Currently, it classifies polyethylene terephthalate (PET), high-density polyethylene (HDPE), polypropylene (PP) and three filled polypropylene grades at 98% precision and recall.

Plastic matrix test

The system is delivered through a Robot-as-a-Service (RaaS) model. It converts an upfront expense into an operating line item, opening advanced sorting to capital-constrained SMEs, particularly in EIT Regional Innovation Scheme (RIS) regions where investment is lacking.

Behind the technical advantages of the solution is its social aspect. CIRPLASTIC offers an easy-to-learn human-machine interaction, which brings seamless integration for line workers, data supervision and maintenance roles.

CIRPLASTIC prototype by Canonical Robots

Building on advanced imaging and machine learning expertise

Canonical Robots transferred its know-how from the KIWISORT fruit-sorting line, where it used hyperspectral imaging and artificial intelligence (AI) to determine kiwi fruit ripeness. This technology formed the foundation for CIRPLASTIC, building on the expertise in advanced imaging and machine learning applications.

As Canonical Robots, we are poised to expand our technological expertise beyond the agro-food sector, specifically targeting the plastic classification domain. The new focus begins with the automotive industry but has broader applicability in the plastic recycling industry as a whole.

Ignacio Secades, Sales & Partnerships at Canonical Robots

Now the CIRPLASTIC system delivers sub-1‰ contamination in a single pass, freeing manufacturers from dependence on virgin plastics. The pilot shows a 9% increase in plastics recovery, translating into significant CO2 savings.

From prototype to end-user testing

The Canonical Robots team received funding from the EIT Manufacturing Empowering SMEs Call 2023 to create a scalable, revenue-generating service. The grant was dedicated to the initial development and testing of the CIRPLASTIC solution, marking the first prototype and testing at an end-user’s facility.

The support from EIT Manufacturing has been instrumental in turning our vision for CIRPLASTIC into reality. Thanks to this funding, Canonical Robots was able to move from concept to prototype and real-world testing with an end-user.

Ignacio Secades, Sales & Partnerships at Canonical Robots

In addition to technological progress, the grant allowed the team to accelerate market readiness and develop training materials that ensure smooth adoption of the solution by recycling plants. Looking back, Secades remarks: “Without this support, our path to scaling CIRPLASTIC and contributing to Europe’s circular economy goals would have been significantly slower.”

Unlocking new opportunities in recycling

Beyond automotive applications, CIRPLASTIC is exploring the potential in the wider plastic recycling industry. The need for efficient and accurate sorting of different plastic types remains a significant challenge. The solution can be a game-changer, providing a fast, reliable and non-destructive method for plastic identification, bringing higher quality and efficiency to recycled materials.

CIRPLASTIC is already being piloted with an end-user. The solution is going at full speed, refining its capabilities through iterative testing and feedback. The ultimate goal for Canonical Robots is to achieve market readiness and secure a place in the European recycling industry by 2028.