Why additive manufacturing skills matter

Additive manufacturing, also known as 3D printing, is gaining momentum across a wide range of industries: from aerospace, automotive, construction, defence, healthcare and medical devices to consumer goods, fashion and food. It accounts for 27% of activities in the global advanced manufacturing industry, making it a leading technology area, according to the JRC report.

Its key advantages – design freedom, customisation, rapid prototyping, weight and material efficiency – enhance manufacturing processes. This, in turn, brings faster production and offers on-demand manufacturing of complex and highly specific parts otherwise difficult or impossible to achieve using conventional production methods. Resource efficiency, cost savings and ultimately sustainability make it even more attractive for the manufacturing industry.

As the demand is growing, so is the need for qualified professionals, from design and engineering to materials science and production operations. To address it, Chiara Bertazzoni, Public Funding Specialist at Kilometro Rosso, walks us through the Additive Manufacturing I and Additive Manufacturing II courses on the EIT Manufacturing Academy platform developed by the EIT Manufacturing-funded project INFINITY. The courses were designed for professionals, workers, students and pupils interested in this field, particularly in engineering.

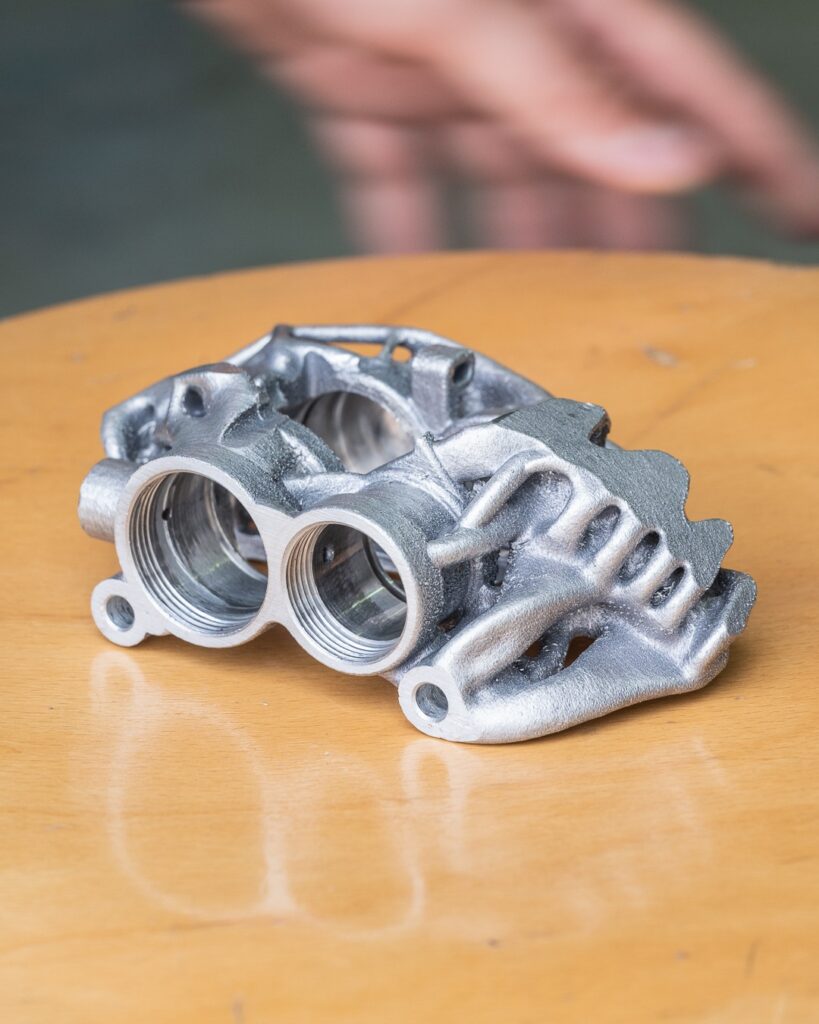

Topologically optimised brake calliper in aluminium (3D printed). Copyright (c) Kilometro Rosso

Uncovering additive manufacturing layer by layer

Despite its many advantages, awareness about the importance of additive manufacturing is still catching up — not only for smarter production, but also as an enabler of the circular economy, highlights Bertazzoni.

To help bridge the skills gap, Kilometro Rosso has teamed up with the INFINITY project to develop two comprehensive online training programmes: Additive Manufacturing I and Additive Manufacturing II. As project coordinator, Brembo analysed the critical skills manufacturers need and implemented the courses within the company to strengthen its workforce. Kilometro Rosso drew on its expertise in technology assessment, materials and economic analysis to shape the learning content. Partners such as Politecnico di Torino and Tecnalia contributed their knowledge on circular economy practices: from remanufacturing to repair in additive manufacturing.

The learning path has a special focus on sustainability and the circular economy. The technical aspects of the courses utilise Kilometro Rosso’s added strength – its laboratory and experts dedicated to additive manufacturing. Now the courses have been awarded an EIT Label, a quality mark for education initiatives from the European Institute of Innovation and Technology (EIT).

Lisa Tech lab with EOS M290 machine. Copyright (c) Kilometro Rosso

The courses cover everything from materials and design principles to circular economy integration and advanced quality assurance. Participants learn how to make informed material choices, prototype smarter and implement sustainable solutions using additive manufacturing.

The learning path is ideal for professionals with at least two years of experience in manufacturing, as well as students and Vocational Education Training (VET) learners eager to acquire in-demand technical competencies. Demand for training has been high – especially among VET students, who have also requested live, interactive (synchronous) lessons, where students interact with instructors in real time.

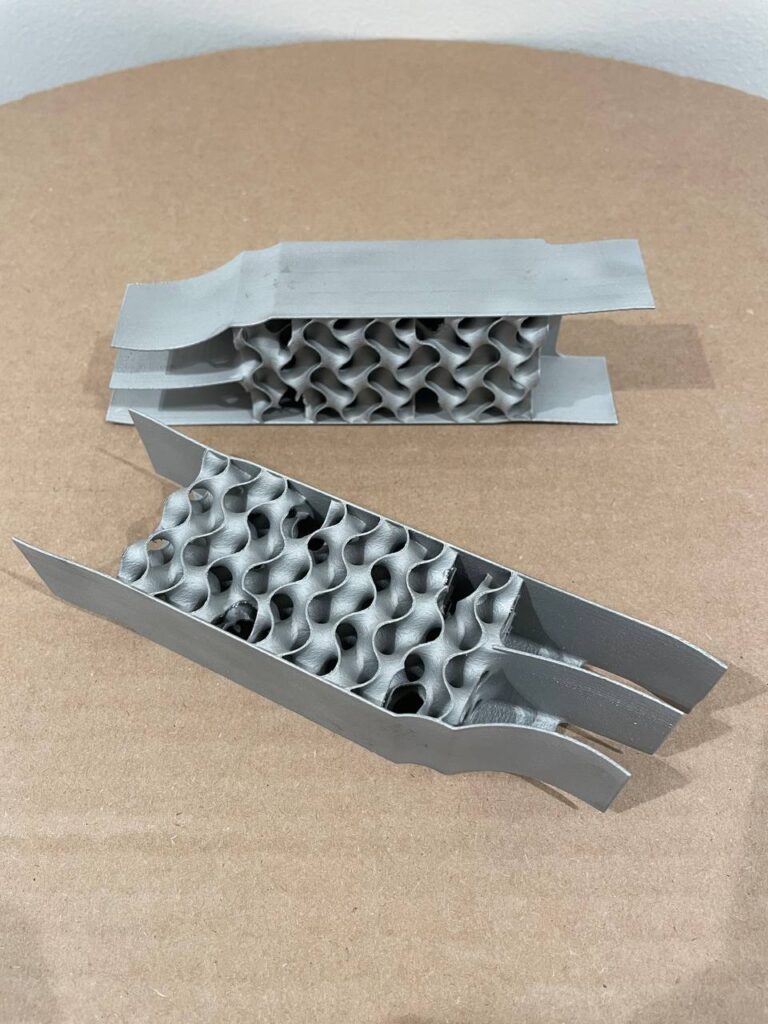

Passive heat exchanger in aluminium (3D printed). Copyright (c) Kilometro Rosso

The future is additive: it’s time to master the in-demand skills

From 2017 to 2023, the interest from VC firms in European companies working on additive manufacturing has more than quadrupled, reports JRC. Materials used for 3D printing include polymers, metals, ceramics and composites. For metal additive manufacturing alone, the global market exceeded USD 18 billion in 2023, with an average annual growth rate of 20–25%, according to the Wohlers Report 2024.

With industry’s transformation and the growing interest from investors, learners of any level can gain in-demand skills and transform manufacturing operations. As the range of sectors applying additive manufacturing is so versatile, the skills acquired in these courses open doors to new career paths, creativity and innovation.

Don’t stay stuck in the past. Step into the world of additive manufacturing for a greener future!

Chiara Bertazzoni, Public Funding Specialist at Kilometro Rosso, encourages anyone hesitating to enrol

Elevate and master your manufacturing skills and knowledge

Discover training courses with EIT Manufacturing Academy!