ZEO Lite project hits milestone in inclusive digital innovation

After a year of collaboration, the ZEO Lite project is coming to a close. Based in Navarra, ZEO Technology teamed up with TASUBINSA – a non-profit that supports inclusive employment – to make factory technology easier and more inclusive. Together, they improved ZEO’s software, which helps digitise data from manual production lines. The updated system is easy to use and works well for people with disabilities or those with limited digital skills.

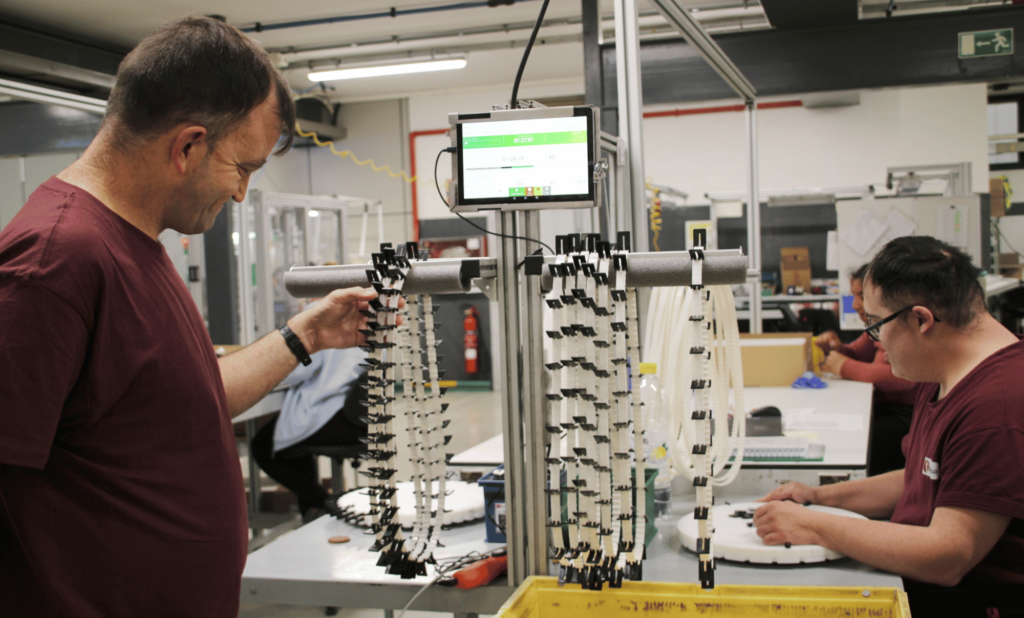

During the pilot phase, the system was tested on a manual production line at TASUBINSA’s Special Employment Center in Tudela. Workers – many with intellectual disabilities – began using tablets and screens to log how many cable-and-motor units they had produced or to report any slowdowns. Their entries were instantly displayed on screens throughout the facility, giving managers a real-time overview of operations. This allowed them to solve problems quickly and plan more effectively.

Giving workers a voice in the process

The system doesn’t just track problems after they happen – it gives workers a voice in the process. Using a tablet or computer, they can flag any drops in efficiency even in advance, for instance when materials are running low, before the line stops. They can also report which work order is being produced and how much they are producing. This real-time input helps prevent unnecessary delays and supports smarter decision-making. As Justo Berganzo from ZEO Technology said: “It’s the workers on the shopfloor who drive the process.”

During the ZEO Lite pilot, managers could see real-time data from the manual production lines, entered directly by workers on the shop floor.

In late May, managers from several TASUBINSA centres attended a live demo – an important milestone for the project. They were impressed by how easily and confidently employees adapted to the new tool and they are now considering expanding the system to more facilities across Navarra, in northern Spain.The live data provided by employees assembling Vending Machines – Plastic Extractor set and its sub-assemblies strengthened communication with departments such as logistics, maintenance and quality control, enhancing the teams’ ability to respond in real time.

Putting people at the heart of innovation

The impact goes beyond just productivity. Being part of a modern, tech-enabled process has had a meaningful effect on the workers’ sense of autonomy. “For employees, it is a major step forward,” said Kontxi Sansiñena, TASUBINSA’s Communication Manager. “This technology empowers people with disabilities to contribute more value.”

For many workers with intellectual disabilities, using digital tools was empowering – a clear reminder that innovation can make jobs better without taking them away.

While digitalisation and automation is often linked to job loss or the need for reskilling, this project shows that manual work still plays a vital role – especially when supported by thoughtful, user-friendly technology. It’s a clear example of how innovation can improve jobs without replacing people. That idea – putting people at the heart of innovation – is also central to the mission of EIT Manufacturing, which co-funded the project through its “Empowering SMEs Call”.

An accessible solution for small businesses

ZEO Lite also meets the goals of that programme by supporting a small business. ZEO Technology successfully created a lighter, more accessible version of its original system, ZEO MES. The new version is simple, affordable and easy to scale – making it a practical choice for other small and medium-sized companies looking to go digital without major upfront costs.

In short, OEE Lite, the commercial brand of this project, is already available on the market, and its people-first approach is its greatest strength. Because empowering people on the shopfloor is the key to achieve operational excellence.