ARIOS

About the project

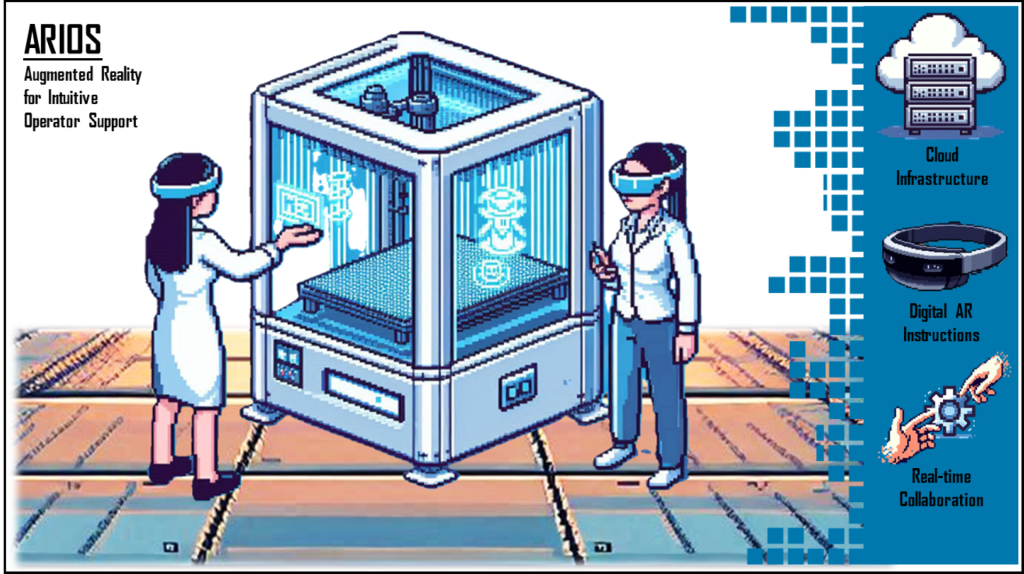

The ARIOS project aims to enhance manufacturing sustainability and efficiency by integrating Augmented Reality (AR) technologies into manufacturing processes. Key objectives include improving operational efficiency, ensuring quality control through artificial intelligence (AI) monitoring, facilitating training and upskilling and fostering collaboration among operators.

To achieve these goals, the project will develop intuitive AR interfaces, integrate AI algorithms for real-time feedback, support multiple devices and prioritise user-centric design based on operator feedback.

Target customers include manufacturing firms seeking to optimise their processes and industrial clients looking for innovative training solutions.

By focusing on these objectives, the project aims to deliver a flexible solution that can significantly enhance manufacturing processes and operator experiences.

Challenges

The main challenges the project aims to address are the inefficiency, inconsistency and error-proneness in manufacturing processes. Current methods often rely on outdated training techniques and lack real-time guidance. This leads to increased production times and quality issues. Studies show that incorporating AR can reduce assembly errors and improve training efficiency.

By leveraging AR technology and providing real time feedback, the product seeks to create a more intuitive and effective assembly environment. Ultimately, addressing this challenge will significantly enhance productivity and quality in manufacturing operations.

Solutions

To address inefficiencies in manufacturing processes, ARIOS proposes an AR-based solution that provides real-time guidance and AI-driven feedback during the manufacturing process. These solutions were identified through stakeholder consultations and industry research highlighting the need for improved training and quality control. Key features include intuitive AR interfaces, multi-user support and real-time monitoring of the process.

Success will be measured through user feedback and performance metrics during the rollout phase.

Expected results

The expected results of the project include significant improvements in assembly efficiency, quality control and operator training. Success will be measured through performance metrics such as error rates, training duration and user feedback during pilot implementations.

Upon completion, the project is envisioned to transform manufacturing processes by providing operators with intuitive, real-time support, leading to higher productivity, reduced costs and improved product quality.

The overall impact will be a more skilled workforce and the promotion of sustainable manufacturing practices across various industries.