CYRUS HD

About the project

This project is focused on the detection of micro and time-evolving surface defects in aluminium extrusion production.

“CYRUS-High Definition” is an advanced inspection system, that provides an inline and real-time detection of micro- and time-evolving defects with the use of artificial intelligence (AI)-powered algorithms applicable in various aluminium extrusion domains.

This innovative project has been designed by D-cube and implemented in collaboration with Alumil S.A., Etem Gestamp Aluminium Extrusions S.A. and HYDRO Extrusion Nenzing GmbH.

Challenges

The existing “promex CYRUS” detection system facilitates real-time detection of common defects and revolutionises conventional approaches with its “die-agnostic” capability.

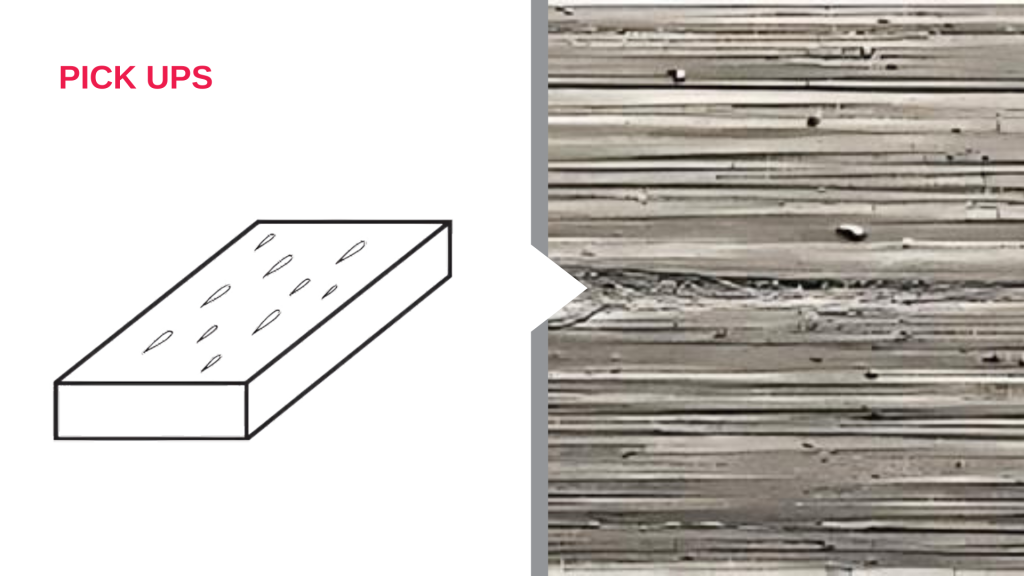

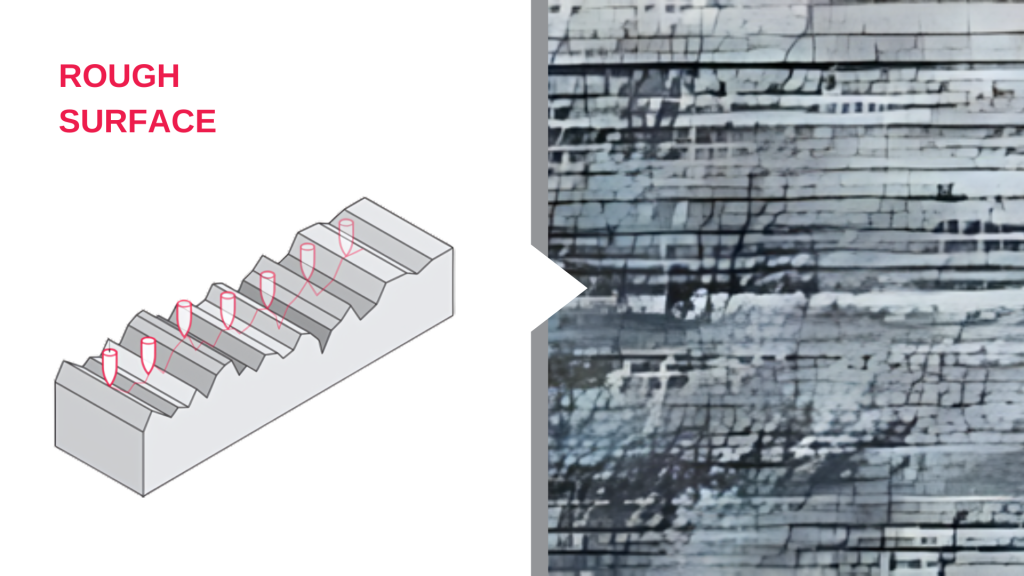

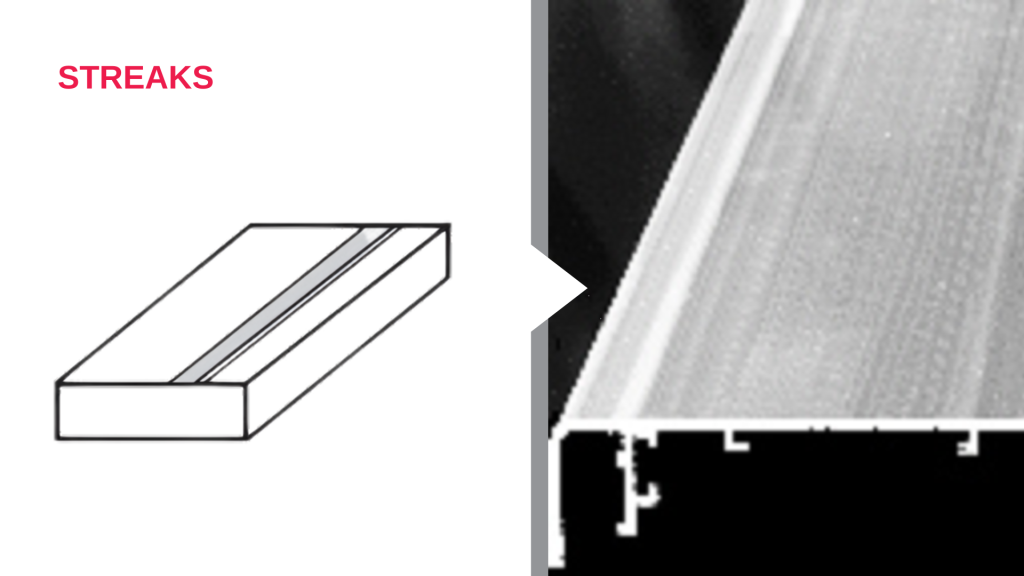

Micro and time-evolving defects detection in aluminium is particularly challenging. These defects are hard to predict and manage as their occurrence rate and appearance vary, and their identification depends on divergence in patterns and textures.

Minor surface inconsistencies can result in severe difficulties for the aluminium industries.

Solutions

CYRUS High-Definition is a sophisticated micro-abnormality defect detection system, that integrates the application of cutting-edge AI-driven algorithms for micro defects allowing both prediction and analysis of time-evolving patterns.

It has high level detection capabilities that utilise ultra-high definition and multi-spectral equipment. The tool facilitates early identification of time evolving defects. It reduces scrap and minimises customer claims as a result of inline and offline corrective actions possible due to early identification.

It is planned that the system will be installed, tested and evaluated with prototypes manufactured for three different aluminium extrusion domains: automotive, architectural and industrial.

Expected results

The goal of the project is to achieve a significant reduction in defective profiles, production costs and unnecessary downstream processing. Specific targets include:

– Reducing scrap,

– Lowering production, processing, and recycling costs,

– Reducing unnecessary downstream processing in secondary production,

– Decrease CO2 emissions while promoting greener growth.

The overall impact of the project is envisioned to enhance aluminium industry efficiency, leading to environmentally and socially sustainable, human-centric manufacturing. This will result in a more sustainable manufacturing process, benefiting both industry and the wider community.