EmpowerWeld

About the project

The main objective of EmpowerWeld is to revolutionise welding processes in industries with highly unstructured environments and highly customised production.

EmpowerWeld aims to develop a self-navigating, human-centric robotic welding solution that will bring about significant positive improvements in manufacturing. It operates agnostic to the environment, reducing costs and improving welding quality. EmpowerWeld prioritises worker well-being and safety, eliminating laborious tasks and toxic fumes.

To accomplish this, EmpowerWeld integrates and combines the following activities:

- Project design and coordination

- Technical advancements for the existing system

- System demonstration and qualification

- Ecosystem development and engagement

- Business development, dissemination and communication.

EmpowerWeld is targeting small and medium-sized enterprises with high-mix low-volume operations. It will initially be deployed in two settings: shipbuilding and fit-for-purpose bicycle manufacturing.

The system can be adopted by businesses which incorporate welding activities as part of their production, manufacturing, or processing pipelines (e.g. aerospace, construction etc.), as well as by welding contractors and fabrication facilities.

Challenges

EmpowerWeld aims to mainly address the shortage of qualified welders in the manufacturing sector. According to recent studies, up to 40% of welding tasks require high-level expertise, exacerbating the skills gap and hindering industry growth. These factors underscore the pressing need for innovative solutions like EmpowerWeld to address the specific demands of the welding sector.

Welding tasks, especially those involving complex geometries, require time, training and high precision to be accomplished. EmpowerWeld is a human-centric solution that facilitates such tasks for the end-user and eliminates the need for increased skillset, allowing for broader inclusion of welders into the workforce.

Solutions

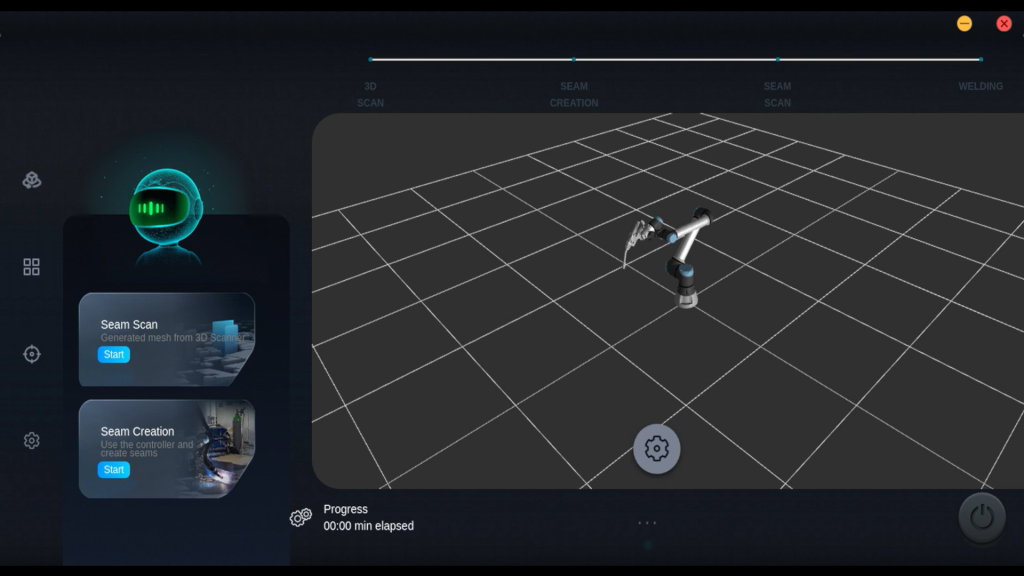

EmpowerWeld addresses welding challenges by incorporating a robotic manipulator, Augmented Reality (AR), and a Decision Support System (DSS). These solutions were identified to enhance precision, inclusiveness, productivity, and resource optimisation in welding.

The workspace is reconstructed via a 3D scanner, enabling the robot to operate safely and autonomously. Technicians trace the welding seam using a six degrees of freedom (6-DoF) device. Using an AR headset, operators verify robot motion and welding result. The robot follows technicians’ input while the DSS optimises welding parameters to reduce resource usage.

This solution delivers an accuracy of less than 5 mm and supports MIG (metal inert gas) and TIG (tungsten inert gas) welding processes.

Expected results

EmpowerWeld is expected to allow operators to control the welding process in a modernised way, improving their productivity and well-being. It is designed to eliminate the need for intensive tasks, thereby improving safety and health. The system will reduce the risk of human errors and accelerate welding processes, improving welding quality and productivity.

The performance of EmpowerWeld will be evaluated according to the following criteria: achievement of the system key performance indicators (KPIs), user feedback and technology adoption surveys. In addition, the project is intended to help change the perception of manufacturing jobs, making them more appealing to a broader segment of society.