Boosting green manufacturing with an upskilling programme

STILWARE is an advanced Computational Design software that enables the design of complex, structured components from flat sheet metal using our proprietary STILFOLD methodology.

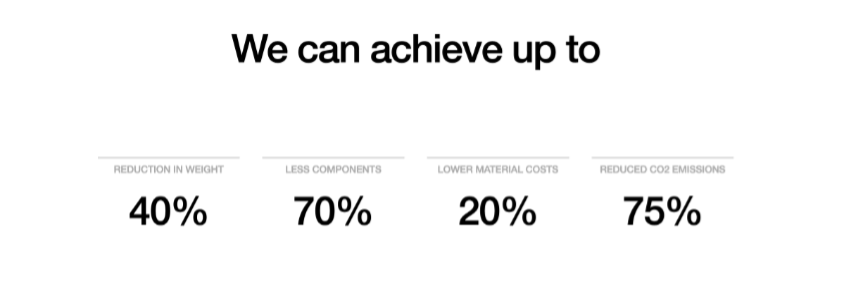

Unlike traditional software that limits design flexibility, this software calculates the unfolding of intricate parts into 2D sheets, allowing designers to replace multi-part assemblies with a single, optimised structure. This eliminates the need for welds, screws, sealants, and separate body panels, reducing weight, material waste, and assembly complexity.

Designers now have the freedom to create mechanically and aesthetically integrated parts that enhance both function and sustainability, bridging the gap between conceptual creativity and real-world manufacturability.

STILTOOL

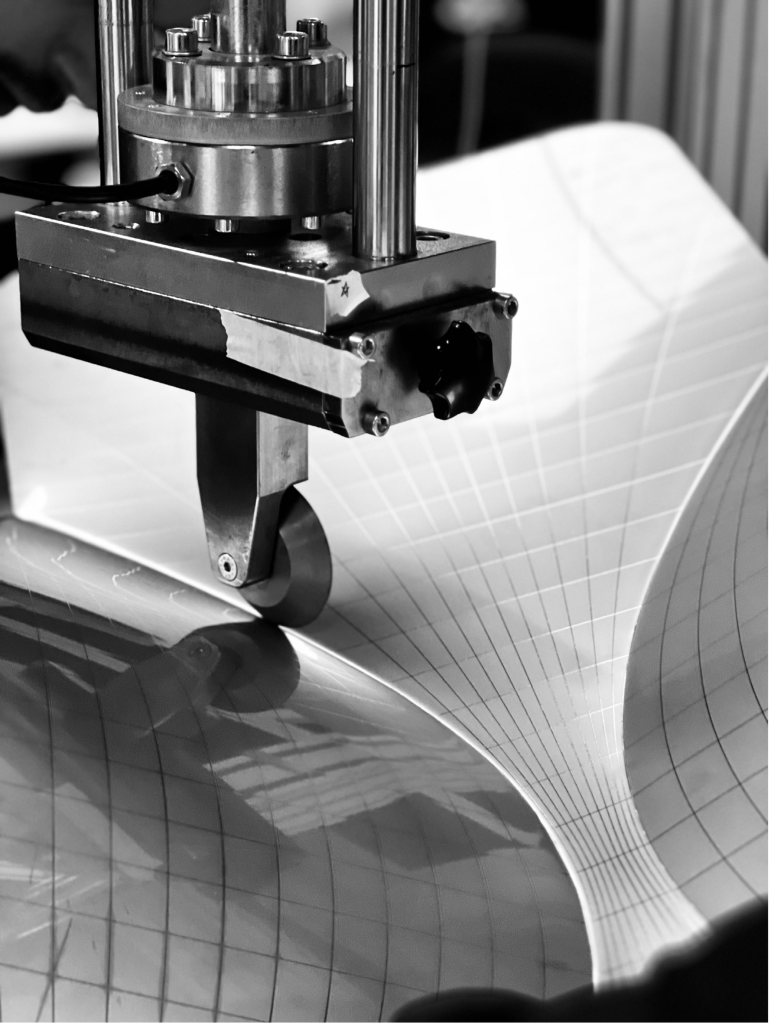

STILTOOL is a robotic application software that converts STILWARE’s computer-aided design (CAD) into folding patterns using CAM (Computer-Aided Manufacturing) instructions, enabling automated robotic folding and forming. This next- generation CAM tool removes the limitations of traditional metal forming, allowing for precise, programmable folding—including along curved lines. By directly integrating AI-powered folding simulations, this tool optimises force application, material behaviour, and structural integrity, empowering manufacturers to produce high-performance metal structures with minimal energy and material use.

STILWORKS

STILWORKS is the physical execution of STILFOLD technology, comprising a robotic production cell equipped with a custom 3-axis wheel system, robotic arms, and adaptive grippers. Unlike conventional press-based systems, this product applies force dynamically from the top, allowing precise, controlled folding without high-impact stamping or welding. The custom grippers provide the unique ability to fold along curved lines and to handle different metal types, making localised, flexible, and modular manufacturing possible.

With an ambition for fully equipped, modular production cells, this product supports on-demand, decentralised manufacturing, reducing transportation emissions and enabling production in both established and remote locations worldwide.

Target market

Ideal for manufacturers seeking flexibility in production—particularly when producing lightweight, high-strength components or testing new prototypes. This product’s free-forming manufacturing capabilities and flexible automation help reduce lead times and respond quickly to changing market demands. Applications range from automotive and mobility (crash beams, chassis parts), to aerospace and defense (lightweight structural components), to consumer goods (durable yet aesthetic metal parts), and general industrial applications.

Societal impact

Beyond technical achievements, this system supports a more sustainable workforce by streamlining repetitive and hazardous tasks, which can then be automated.

This shift not only enhances worker safety but also upskills labour, as operators learn to oversee the advanced software and robotics involved.

From a broader sector perspective, this solution represents a step change in sustainability. It directly addresses circular economy principles by reducing raw material waste and eliminating carbon emissions through localised manufacturing.

The environmental and societal gains—from reduced energy use to minimised scrap—contribute positively to EU-wide goals for greener production, and its potential to lower the barrier to entry for cutting-edge manufacturing can strengthen European industrial competitiveness.