VRSafe

About the project

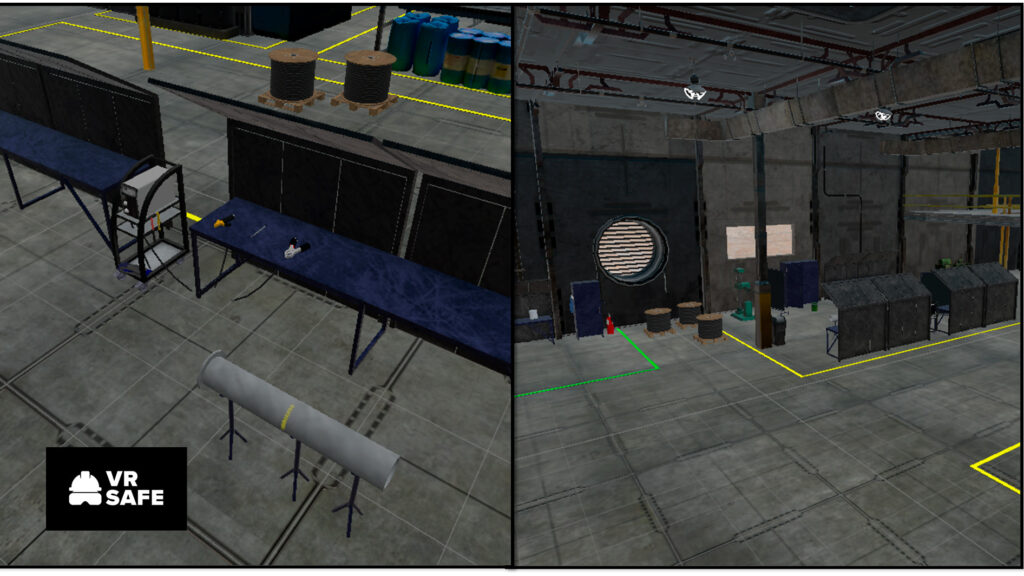

VRSafe aims to create a safer workplace by introducing a virtual industrial environment for training operators in safety related processes. By using virtual reality (VR), trainees become more equipped to handle hazardous situations effectively.

The VR platform is offered in two forms:

- as a package with generic safety scenarios for a broad audience, encompassing virtually all domains where human safety and well-being must be ensured,

- as customised safety training VR scenarios built on customer requirements.

Within VRSafe’s virtual environment, trainees can repeatedly engage with various scenarios, enhancing their skills and reducing their exposure to real-life dangers.

Challenges

The main challenge VRSafe addresses is the difficulty of providing effective, consistent and engaging training in high-risk environments. Traditional methods expose trainees to real hazards and provide variable quality content, leading to inconsistent safety knowledge and skills.

VRSafe’s immersive VR simulations offer a controlled, risk-free environment, ensuring uniform training quality with increased engagement. By leveraging VR technology, companies can enhance safety training outcomes, ultimately creating a safer workplace.

Solutions

VRSafe addresses the challenges of high-risk training environments, variable quality and employee engagement in safety training with a comprehensive VR training platform. Realistic simulations provide a risk-free, immersive learning experience, ensuring consistent, high-quality training delivery. Interactive elements and gamification enhance engagement and retention.

Developed with guidance from safety experts, the simulation scenarios and real-time notification feedback create a safe, engaging and effective training solution. By leveraging cutting-edge VR technology, VRSafe equips employees to handle hazardous situations confidently, fostering a safer, more efficient.

Expected results

The VRSafe project aims to develop an engaging VR safety training solution with generic and customised scenarios to improve safety awareness and skill retention. Success will be measured by high user satisfaction, reduced onboarding time, enhanced safety compliance and safety training-related incidents.

The project envisions creating safer work environments, reducing new hire anxiety and providing consistent, high-quality training experiences, ultimately leading to more confident and capable employees and improved operational efficiency.

About the solution: VRSafe

This product offers virtual reality (VR) environments for operators training towards safe and human-centric workplaces.

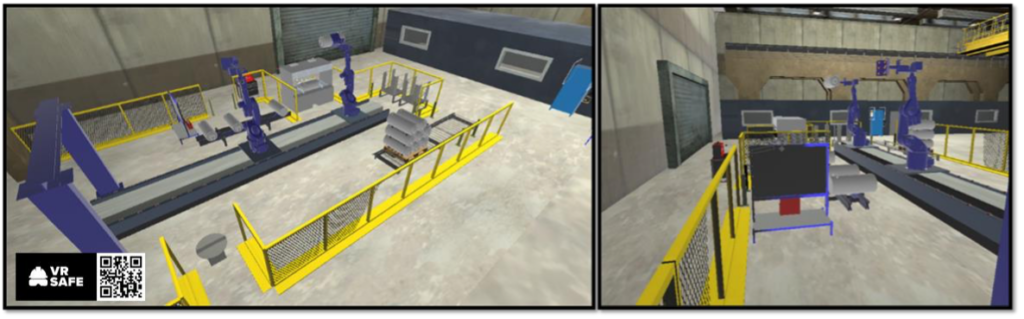

There is a core VR training platform. It includes an advanced virtual reality simulation system with a unified architecture, enabling highly immersive training experiences that replicate real manufacturing environments with precise detail.

It offers a dual scenario portfolio.

- Generic scenarios: pre-built simulations covering universal manufacturing operations (crane maintenance, welding, fire hazards, forklift operations, robot programming).

- Customised scenarios: tailored environments precisely matching specific industrial settings and processes.

Target market

Primary markets include manufacturing industries requiring regular safety training and high-risk operation preparation, such as:

- Heavy manufacturing and industrial processing.

- Automotive industry (demonstrated through BREMBO implementation).

- Energy sector.

- Chemical processing.

- Industrial equipment manufacturing.

The key applications of the product include:

- New operator safety training.

- Periodic safety requirement certification.

- High-risk procedure practice.

- Equipment operation training.

- Emergency response preparation.

Societal impact

The solution strongly aligns with EIT Manufacturing’s core objectives. By placing people at the centre of manufacturing innovation, the platform empowers employees through cutting-edge training tools that prioritise their safety and professional development.

The solution contributes to green manufacturing by reducing the environmental impact of traditional training methods through virtualisation, eliminating the need for physical resources and minimising waste.

Finaly, the product fosters European sovereignty and competitiveness by developing advanced technological capabilities within the EU manufacturing sector, helping European industries maintain their competitive edge through enhanced safety standards and operational efficiency.

This product represents a transformative leap forward in manufacturing safety training with its combination of immersive VR technology with sophisticated learning mechanisms. As Industry 4.0 continues to evolve, this product stands poised to play a pivotal role in shaping the future of manufacturing safety training. In this way, it will contribute to a more resilient, efficient, and safety-conscious manufacturing sector across Europe.