ZEO – LITE

About the project

ZEO Technology has helped industries from different sizes and sectors to improve their productivity through the implementation of ZEO-MES and ZEO-OEE platforms. These platforms are based on a combination of hardware that automatically captures data from machines and software (combining real-time dashboards and analysis solutions).

However, industrial companies have manual productive processes which are not related to machines (eg manual assemblies and manual packaging activities). Currently, part of the information about production and incidents is recorded by workers on paper. Therefore, exploitation of information is limited and a real-time analysis is not possible.

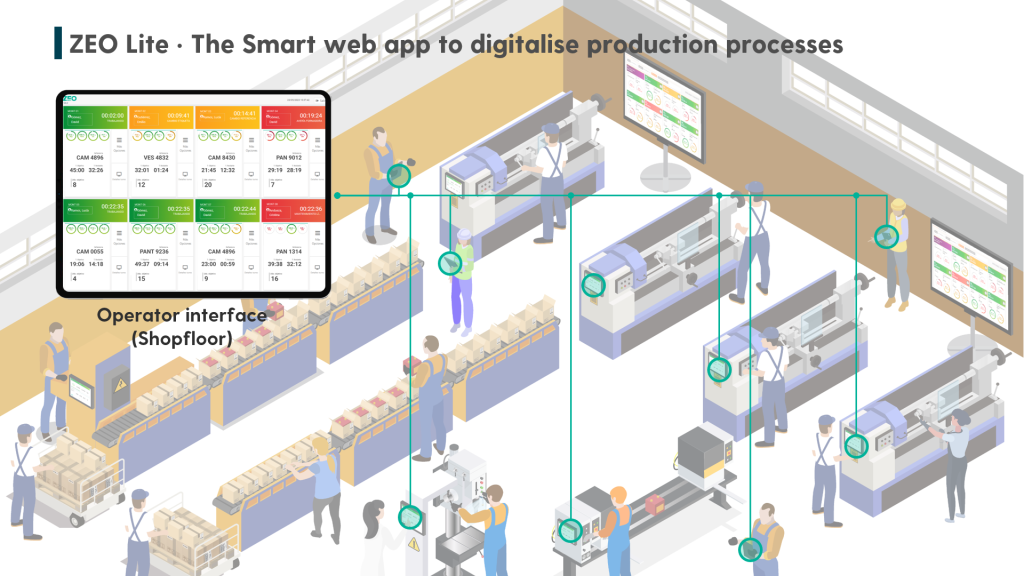

ZEO LITE is a smart web app intended to digitalise production processes that involve data manually fed by workers. It will support the easy reporting of inefficiencies, production and defective products.

The product will empower the workforce and managers to make operational decisions by offering real-time monitoring of production. It will provide the ability to analyse overall equipment efficiency (OEE) key performance indicators (KPIs), such as availability, performance, quality.

Challenges

The product requires workers to provide real-time production data. Thus, backend and frontend technology must be designed to maximise the user experience, regardless of the digital skills of workers.

The use-case (TASUBINSA) is an industry with a mission to include disabled people and people at risk of social exclusion. Many workers participating in the pilot tests are low-skilled individuals.

The technological frontend of the product will set up a simple system to improve the reporting of incidents and production counters. The system will be designed to increase proactive actions and consequently increase production effectiveness.

Solutions

The product is a high technology platform based on state-of-the-art backend, databases and frontends. It is an agile, visual and intuitive web platform which connects people to manufacturing plant reality.

It is a cable-free system able to run in the Cloud. It can operate as SaaS and the startup implementation phase follows immediately after configuration.

It is a light version of a manufacturing execution system (MES) which can be easily scaled and complexed (eg interoperability). It can serve as a gateway to digitalisation for many companies based on manual processes or with lower level of automation and digitalisation.

Expected results

The main results of the project are expected to be as follows:

- ZEO LITE will be an easy-to-use platform which is adapted to workers with any degree of digitalisation.

- The two-phase experimental test (first a preliminary pilot and secondly an extended pilot) will confirm the easy scalability of the solution.

- The efficiency indicators of the industrial use-case will improve by more than 5% during the project. These KPIs will be measured by ZEO LITE OEE indicators.

This product has the potential to make a direct and important contribution to the optimisation of production processes and resources efficiency in the companies where it is installed.