About the project

About the project

The RAPTOR project, embodying a circular business model, represents a pioneering stride in sustainable development and the digital transformation of manufacturing. RAPTOR introduces groundbreaking techniques by integrating custom-designed electromagnet and Hall-probe scanning systems within 3D printers.

This innovation ensures the precise alignment of anisotropic powder, dramatically improving product efficiency. Crucially, it facilitates the utilisation of recycled materials from end-of-life permanent magnets. The project is committed to clean production technologies and remanufacturing, effectively bridging the gap between early product design phases and the end product.

Its activities are expected to lead to an increase in the use of remanufactured products, facilitating a tangible shift towards a sustainable industrial landscape and supporting circular business models.

Challenges

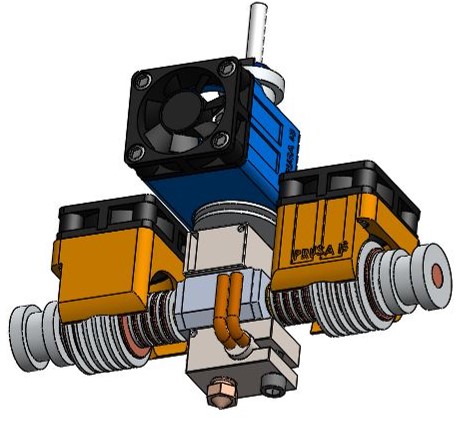

This works pushes at the cutting edge of manufacturing by building a 3D printer specifically engineered for permanent magnets, designed from the ground up with meticulous attention to every detail. This innovation substantially improves the precision possible, which will have significant applications in material science and industry.

Solutions

The project is composed of two parts:

- 3D printer for magnetic materials:

- The 3D printer uses precision engineering. It is custom-built to handle recycled magnetic materials, especially permanent magnets, with high accuracy and reliability.

- It uses advanced software, which ensures accurate management of magnetic properties during printing.

- Its expected performance is at least 95% accuracy in prints and 99% uptime.

- Custom-designed permanent magnets:

- These offer tailored prototyping, which means it can create magnets with specific properties, shapes and sizes.

- It has a rapid turnaround, offering a 70% reduction in lead times for custom magnets.

- It contributes to the circular economy by using recycled raw material from end-of-life permanent magnets (97% material yield) with zero waste.

Expected results

The expected outcomes include:

- Industry Leadership: Position the company as a leader in the 3D printing of magnetic materials and custom-designed magnets, driving innovation in multiple sectors including automotive, aerospace and electronics.

- Enhanced Prototyping and Production: Significantly improve the way industries prototype and manufacture permanent magnet components, enabling faster, more flexible and cost-effective production.

- Sustainability: Foster sustainability by offering cutting-edge solutions that meet the evolving demands of the permanent magnet market.