Online rheological monitoring and automated control loop of the compounding process for maximised incorporation of recycled plastics

About the project

Increasing the recyclate’s content in new brand plastic products is nowadays of high environmental relevance. RhePlaCe will enhance this task by using upgraded control tools.

Purpose of the project

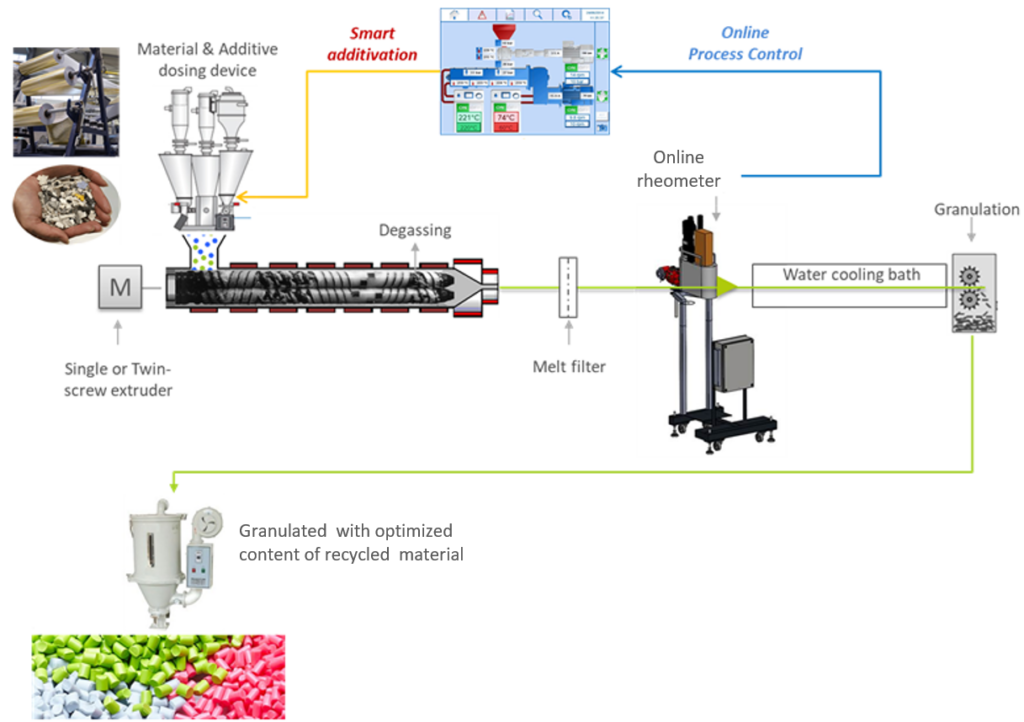

RhePlaCe aims an automated control loop fed up by online fluidity data obtained during twin-screw extrusion to maximize the addition of recycled materials in plastics products.

Societal impact

RhePlaCe will foster the plastics recycling activity and circularity while keeping the added value of new brand plastic consumer goods based on optimized recyclate’s content.

Main results & insights

Validation of an efficient performance of the automated control loop in two representative use cases: plastics for automotive applications and plastic consumer goods.

Quote from the Activity Leader

RHEPLACE is a concrete solution to foster plastic circular economy thanks to qualified secondary raw material

Ronan Le Goff, R&D Programme Manager, IPC

Participants

LEAD PARTNER

CT-IPC

France, BELLIGNAT, Core partner

PARTICIPANT

Axel’One

France, Solaize, Associate Partner

PARTICIPANT

OPTIMISTIK

France, CHAMBÉRY, Associate Partner