TraceCO2

About the project

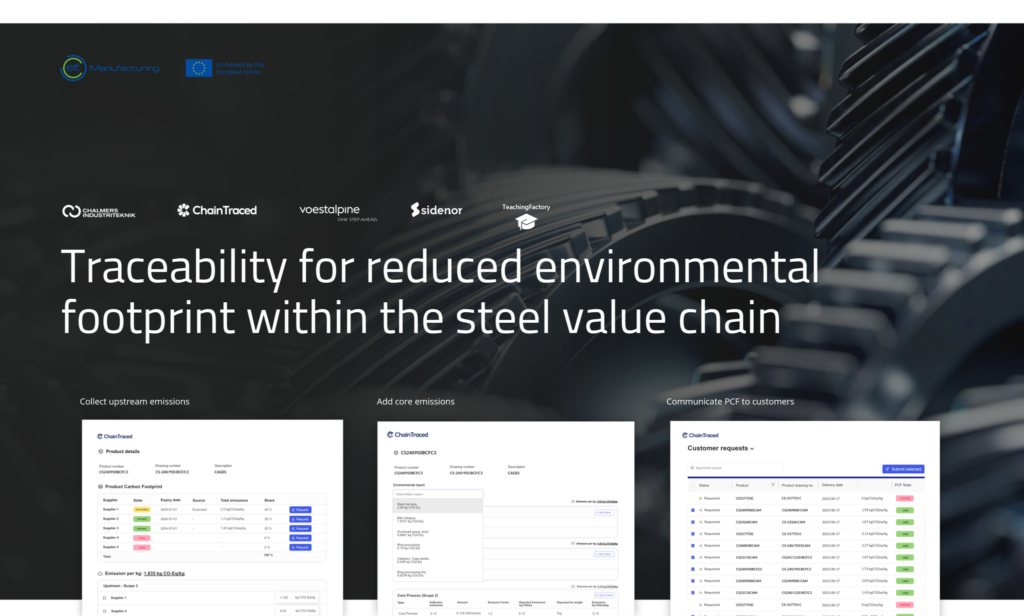

The primary goal of this project is to launch a European initiative that empowers secure and efficient Product Carbon Footprint (PCF) accounting practices specifically for the steel industry. This includes a digital platform based on reporting standards relevant to the industry. It aims to facilitate reliable emissions data sharing and reduce ownership costs across the whole steel value chain, from mining to original equipment manufacturers (OEMs). It also supports collaboration within key segments of the metallic value chain, bringing stakeholders together to achieve net-zero targets, promote innovation, sustainability and shared learning.

Thus, the purpose of this activity is to:

1. Define, align and implement CO2 equivalent reporting methods and frameworks that are standardised and verifiable, and which can be applied at product and transactional levels.

2. Initiate the scale up of a traceability platform to enable increased visibility of CO2 equivalent emissions and material composition.

3. Validate traction within current contact networks. An acceleration of marketed activities is planned across the manufacturing value chain in Europe.

Challenges

Sharing emission data transparently across the steel supply chain network in a verifiable and standardised format is challenging. Studies show the steel industry’s significant role in global carbon (11%) and greenhouse gas emissions (8%). These emissions mostly originate outside internal operations, with over 90% being Scope 3 emissions.

Current accounting practices for emissions tracking pose a burden on the value chain’s total cost of ownership. Manual and resource-intensive, these practices lack reliable primary data and allow room for interpretation. To drive sustainability, collaboration, efficiency, and transparency it is necessary to adopt more reliable approaches to share critical product information.

Solutions

Through comprehensive data integration, real-time monitoring, analytics and enhanced collaboration, ChainTraced is working to transform the steel industry’s approach to emissions reduction.

The goal is to broaden and democratise access to emissions data distribution capabilities. This is why the project’s ambitious vision extends beyond the TraceCO2 consortium, aiming to inspire widespread adoption of our initiative and platform and foster a sustainable future across industry.

Expected results

It is intended that the ChainTraced platform will have the following impact on the steel lifecycle stages:

- Input materials: making it possible to obtain real supplier data to reduce CO2 equivalent emissions for different input materials to enable companies to choose the most sustainable sources.

- Manufacturing: facilitating the collection of internal emission datasets within production for the purpose of supporting the optimisation of energy-efficient manufacturing processes to minimise CO2 equivalent emissions.

- Production and technology use: accessing data analytic capabilities to enable comparison of different production technologies and helping to reduce waste and improve efficient energy consumption across the product lifecycle.

- End of life: to support better understanding regarding material composition within products to improve end-of-life handling of the product.