HCP Sense and EIT Manufacturing sign support agreement

HCP Sense have turned a rolling bearing into a sensor. Thus, their sensor bearing can be easily integrated into existing machines and requires only minimal alterations to enable electrical contact. EIT Manufacturing is excited to support the start-up in their development!

Measurement of the acting forces in a machine provide a wealth of information about its condition. This information enables predictive maintenance wherever something moves – which is almost in every machine in manufacturing and beyond. So far, integration of sensors for force measurement has been tricky and often involved changing the mechanical design of a machine.

“The HCP Sense sensor bearing has the same dimensions as a conventional bearing, and therefore can be integrated easily into the pre-existent structure,” explains Ansgar Thilmann, founder and Managing Director at HCP Sense. “The only thing we need to do is facilitate the electrical contact, which can be achieved with minimal design adjustment. This means that the sensor bearing can be easily added to existing systems and is an economical solution for acquiring valuable data.”

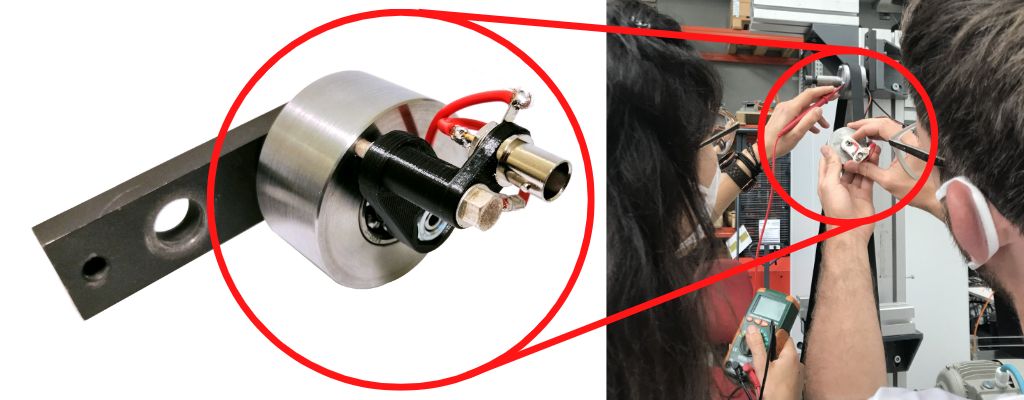

The sensor bearing while being tested on a test rig.

The development of the sensor is based on research on the electrical properties of rolling bearings, conducted at the Institute for Product Development and Machine Elements (PMD) at TU Darmstadt. The patented method uses the electrical impedance of the bearing to determine its load and lubrication condition. Because the bearing itself is the sensor, no additional technology needs to be integrated into the system, and therefore no additional installation space is required.

Once integrated, the sensor bearings measure forces, monitor lubrication quantity and quality and detect damages in rolling bearings. As an industry 4.0 application, not only do the sensor bearings enable predictive maintenance and improvement of manufacturing processes, but also new digital business models thanks to the data generated.

The HCP Sensor bearings measure forces, monitor lubrication quantity and quality and detect damages in rolling bearings.

Wolfgang Kniejski, Senior Business Creation Manager of EIT Manufacturing, points to the market potential of the sensor bearings: “Rolling bearings are literally everywhere: The HCP sensor bearings can be integrated in a variety of industries, be that machine and plant construction, special mechanical engineering, renewable energy, mobility sector, utility vehicles and many more. It’s exciting to help bring this technology to market.”

HCP Sense was founded by Dr Georg Martin, Sarah Wicker, Dr Tobias Schirra, Ansgar Thilmann (image at the top) as a spin-off of TU Darmstadt TU Darmstadt. Although TU Darmstadt is located near the EIT Manufacturing Central team which now supports them, it was another start-up, AR-Experts, who made the first connection between the two parties.

Having started as a research project at TU Darmstadt, the HCP Sense team was awarded the EXIST Forschungstransfer grant in November 2020. First prototypes are already in use and are being operated by various customers, under diversified conditions.

HCP Sense welcomed their new team member in August 2022. More information and further news on their website.