Human-Centric Preference-based Optimisation

About the project

The HCPbO project aims to develop, test, and validate two optimisation algorithms with an accompanying graphical user interface (GUI). Unlike traditional quantitative optimisation, these algorithms use qualitative feedback, relying on user preferences rather than numerical cost functions.

The method targets optimisation problems where the decision-maker cannot quantify the objective function but can express preferences between different decision vectors (eg “this is better than that”). The algorithm iteratively proposes new comparisons based on active learning from past decisions and preferences, refining a surrogate of the latent objective function. Users compare process outcomes, guiding the algorithm to update its internal model and suggest new settings. This process repeats until an optimal solution is found, allowing for effective optimisation based on qualitative feedback.

There are no specific target user groups. In fact, the software components will be general and applicable to any process or application requiring static tuning of their parameters (eg machine tuning for maximising output performance).

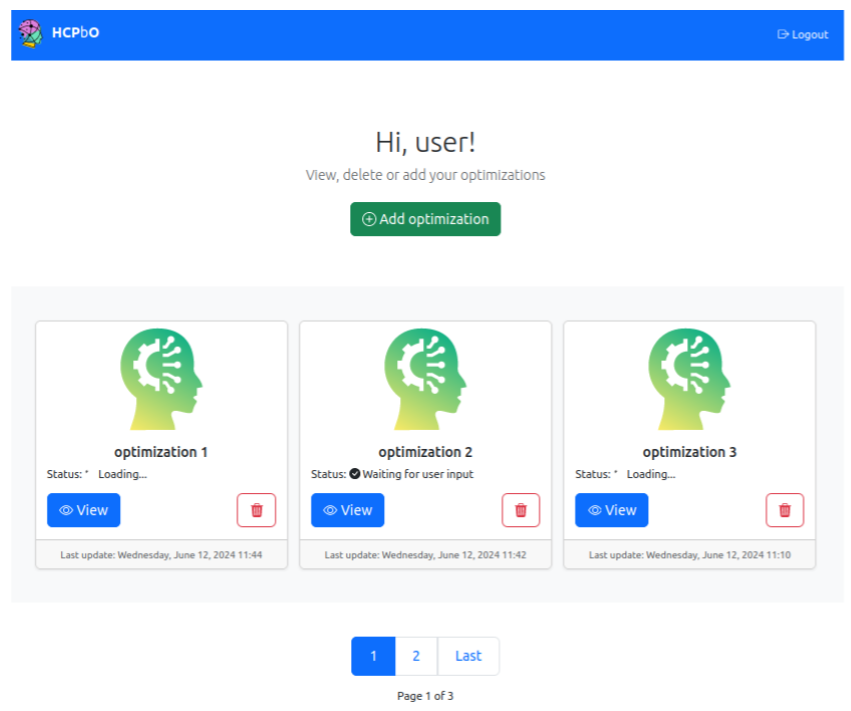

In addition, the proposed software components will give non-expert programming users the ability to exploit advanced artificial intelligence (AI)-based algorithms for process optimisation purposes. This will be possible by means of the GUI, which improves the usability of such algorithms by providing an intuitive means of interaction between the user and the methodologies.

Challenges

The HCPbO framework assists users in optimising industrial processes without requiring programming skills, placing experienced operators at the center of the production environment. This human-centric approach reduces manual tasks, leverages expert knowledge, and requalifies lower-skilled operators.

By integrating digital algorithms, the solution optimises critical processes, enhancing digitalisation and connecting production plants with software components. The framework reduces manual labour, setup time, costs, human resources, energy consumption and materials. HCPbO offers a novel AI-based solution for optimising processes and machinery, improving efficiency and reducing the need for manual intervention.

Solutions

The HCPbO project focuses on developing and validating two optimisation algorithms with a user-friendly GUI. These algorithms use qualitative feedback based on user preferences, ideal for situations where objective functions cannot be quantified. The algorithm iteratively refines its model through comparisons, guiding users to optimal solutions.

Applicable to any process needing parameter tuning, the software is versatile and accessible to non-experts. The GUI simplifies the use of advanced AI-based algorithms, allowing effective process optimisation without programming skills. The software is designed for broad applicability, easing interaction between users and the methodologies.

Expected results

The solution is being tailored to the specific needs of each of the two use cases (TEC-EUROLAB and SMARTZAVOD) to gain insights for developing a generalised solution. This broader solution will target small and medium-sized manufacturers across Europe, initially focusing on SANTER’s customer base in Italy, Germany and beyond.

While the solution will be as generalised as possible, it will require customisation for each configuration process. The pricing model will include an estimate developed following an initial consultation, with costs varying based on labour, materials and the complexity of the manufacturing process.

About the solution: HCPbO – Human Centric Preference based Optimisation

The project delivers an advanced optimisation tool with the following key features:

Preference-based optimisation algorithm

A qualitative optimisation algorithm that allows operators to provide feedback based on preferences (e.g., “this is better than that”), guiding the optimisation process. This approach is ideal in scenarios where quantitative metrics and sensors were unavailable, offering a programming-free interface for operators.

Hybrid optimisation algorithm

The tool combines both qualitative and quantitative optimisation features. By fusing Bayesian optimisation and preference-based optimisation, this algorithm maximises the flexibility and performance of the optimisation tool, making it suitable for various industrial processes and enhancing the system’s adaptability.

Transfer learning capabilities

The algorithm benefits from transfer learning, enabling the model to generalise across similar processes. This reduces the time and resources required for tuning similar processes, enhancing the tool’s efficiency and effectiveness across different industrial applications.

User-friendly interface (GUI)

The tool includes a highly customisable GUI that simplifies the optimisation process for non-expert users. Operators can interact intuitively with the system, defining optimisation variables and monitoring process performance without needing advanced programming skills.

Scalability and flexibility

The solution is designed to be applicable across various industrial sectors, providing a general-purpose optimisation tool. It can be adapted to specific use cases, such as optimising Industrial Computed Tomography (CT) scans or hybrid 3D printing processes, ensuring broad applicability in different manufacturing contexts.

Target market

The solution is designed for manufacturers across a wide range of high-value sectors, including aerospace, automotive, and additive manufacturing. It particularly benefits industries where precise process optimisation is critical but where sensors or quantitative metrics may be limited.

Key applications include the optimisation of Industrial Computed Tomography (CT) scans in sectors like aerospace and automotive for non-destructive testing, and the optimisation of polymer printing and post-processing parameters in hybrid 3D printing for industries such as automotive, consumer goods and medical device manufacturing.

The solution provides the most value in environments where operators need to adjust complex parameters—such as temperature, speed, and material properties—without the need for advanced programming skills. It allows manufacturers to improve the quality of their products, reduce errors, and significantly cut down on setup times, making it a perfect fit for industries requiring both high precision and flexibility in their manufacturing processes.

Societal impact

The proposed framework aims to assist users in advanced optimisation procedures for industrial processes. In doing so, it allows for the exploitation of their expertise to tune high-added-value processes without requiring any programming skills. Even lower-qualified operators with extensive experience in critical processes are placed at the centrer of the production environment. Therefore, the proposed framework is human-centric, reducing manual and repetitive tasks while leveraging the knowledge of expert users and requalifying the work of low-skilled operators.