Pan-European network for more innovation in manufacturing

Downloads below

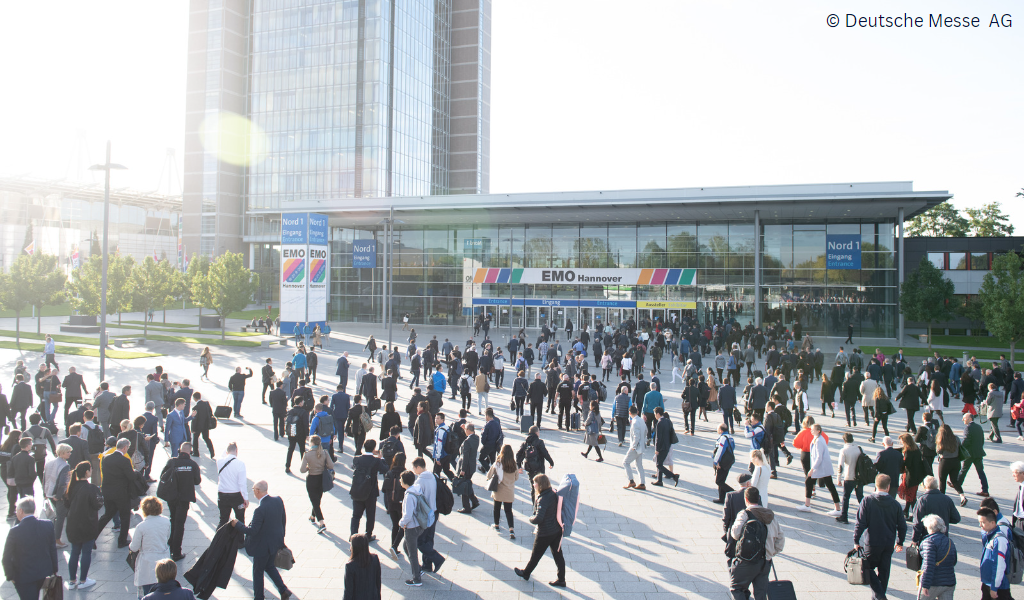

EIT Manufacturing is Europe’s largest innovation ecosystem for the manufacturing industry, which brings together innovators, research institutes and companies. Under the motto “Connecting the dots”, the organisation will have three booths in hall 9 at EMO Hannover 2023.

It will present 20 start-ups (location: E34), its services in innovation and business creation (location: B40) as well as an ecosystem of funded projects focused on manufacturing data spaces (location: H22). EIT Manufacturing is one of nine knowledge and innovation communities supported by the European Institute of Innovation and Technology (EIT), a body of the European Union.

As an innovation network, “connecting the dots” is at the heart of all EIT Manufacturing activities, which focus on innovation, education and business creation. “EIT Manufacturing connects all players of manufacturing – industry and start-ups, start-ups and investors, academia and industry, to name but a few,” says Dr Christian Bölling, Director EIT Manufacturing Central.

Our aim is to move manufacturing innovation forward, because we are convinced that you only need the right people in the room to find a good solution to issues manufacturing faces. Whether this is how to use data to best advantage, how to boost competitiveness by means of artificial intelligence or how to monitor and decrease energy consumption – at least one member of our pan-European network will have an answer to this.

Dr Christian Bölling, Director EIT Manufacturing Central

EIT Manufacturing – the European innovation network for manufacturing

The organisation supports companies looking for innovative solutions to their challenges, provides start-ups with opportunities to pilot their solutions in production environments, opens doors to new markets or market segments and attracts financing. Additionally, EIT Manufacturing publishes its own calls for proposals and also takes part in funded projects as a project partner.

Location at EMO: Hall 9 | Booth B40

From project to ecosystem – Europe’s pioneering data space projects in manufacturing

EuProGigant, short for “European Production Giganet” a binational project funded by German and Austrian authorities, is a project which aims to achieve smart and sovereign use of data in the European manufacturing industry.

Over time, this project has turned into an ecosystem of projects around data spaces which focuses on the simple and secure exchange of machine data and services. But how to build a trusted ecosystem? Using Gaia-X, the five pioneering research projects AMIDS, DIONE-X, EuProGigant, ESCOM and Flex4Res are working on a joint ecosystem for various industry needs, such as strengthening supply chain resilience, assessing carbon footprints in the product design phase or addressing balanced edge cloud environments for sovereign component service systems, to name a few. Together they demonstrate how data can support the industrial value-creation process while describing the benefits of data-driven business models. These efforts support the relocation of production companies back to Europe.

Visitors of EMO Hannover can experience the projects live with their demonstrators at the ecosystem booth and learn more about

- the possibility to minimise search efforts for product assembly and achieve a higher speed of value creation (EuProGigant),

- how an Asset Administration Shell could look like and how to create and use a digital twin (Flex4Res),

- how data quality can affect the algorithm and AI prediction quality (DIONE-X).

Location at EMO: Hall 9 | Booth H22

AMIDS: The Austrian Manufacturing Innovation Data Space (AMIDS) will be the main result of the Lin-X projects (PilotLin-X und ResearchLin-X). With the support of academic and industrial partners, the pilot factories of the JKU Linz, TU Graz and TU Wien will be interconnected to allow for the demonstration of the co-design and co-production of production parts. In doing so, companies will have a sustainable, low-threshold contact point for complex innovation projects and easy access to data spaces.

DIONE-X: Open and secure data exchange along the entire process chain of the machining industry – this is the goal of the DIONE-X research project. By building an efficient and secure data and service ecosystem based on the principles of Gaia-X, DIONE-X enables ecosystem participants not only to exchange data across companies but also to create new fields of application, including data-driven business models. In three use cases, project partners from research and industry will develop standards and guidelines that are essential for building this value network.

EuProGigant: The Austrian-German Gaia-X lighthouse project EuProGigant stands for the vision of a smart, resilient and sustainable European manufacturing industry. By March 2025, the project team will set up a multi-location, digitally networked production ecosystem. In interaction with Gaia-X, EuProGigant not only enables sovereign data management but also offers a new dimension in the analysis of the companies’ own production processes by making cross-company data value chains in a multi-platform ecosystem describable. EuProGigant is also member of the GEN-X network.

ESCOM: The ESCOM research and innovation project – Edge Services for Components – focuses on balanced edge cloud environments for sovereign component service systems in the production environment. The project both tests the advantages of edge computing in industry-related application scenarios and illustrates the guiding principles of a Gaia-X-compliant data and service ecosystem. The framework of the two application scenarios is metalworking discrete manufacturing.

Flex4Res: The European research project Flex4Res aims to improve the resilience of supply chains. An open platform based on the principles of Gaia-X will enable secure and sovereign cross-company data exchange. Combined with additional toolboxes for resilience assessment and reconfiguration planning, stakeholders across the supply chain will be enabled to manage different types of disruptions by reconfiguring supply chains and production lines quickly and efficiently.

Start Up Area and Access to Tech-Event

In the dedicated Start-Up Area, EIT Manufacturing will feature 20 promising European start-ups from the EIT Manufacturing community. For two three-day periods, one from 18 to 20 September, the other from 21 to 23 September, they will showcase their innovative solutions at the collective stand.

Additionally, these start-ups will participate in an Access to Tech event, which aims to connect industrial corporations seeking groundbreaking solutions for their challenges and start-ups and scale-ups from the extensive EIT Manufacturing portfolio. The Access to Tech event will give stage time to the participating young companies, in which they will pitch to the audience at EMO Hannover. After this, start-ups and industry representatives will meet for one-to-one conversations to explore collaboration opportunities.

Location at EMO: Hall 9 | Booth E34

Background information

-

EIT Manufacturing is supported by the European Institute of Innovation and Technology (EIT), a body of the European Union, and it is one of nine innovation communities within EIT. EIT Manufacturing’s main goal is to bring European stakeholders focused on manufacturing together in innovation ecosystems that add unique value to European products, processes and services and inspire the creation of globally competitive and sustainable manufacturing. EIT Manufacturing brings together more than 80 members from universities, research institutes and business.

-

The European Institute of Innovation and Technology (EIT) strengthens Europe’s ability to innovate by powering solutions to pressing global challenges and by nurturing entrepreneurial talent to create sustainable growth and skilled jobs in Europe. The EIT is an EU body which is an integral part of Horizon Europe, the EU Framework Programme for Research and Innovation. The Institute supports the development of dynamic pan-European partnerships – EIT Knowledge and Innovation Communities – among leading companies, research labs and universities.