Simulation needed for resilient operations

Image credit: https://www.plm.automation.siemens.com

Image credit: https://www.plm.automation.siemens.com

How can we, very fast, reorganise production so that disruptions have the minimum impact?

Description

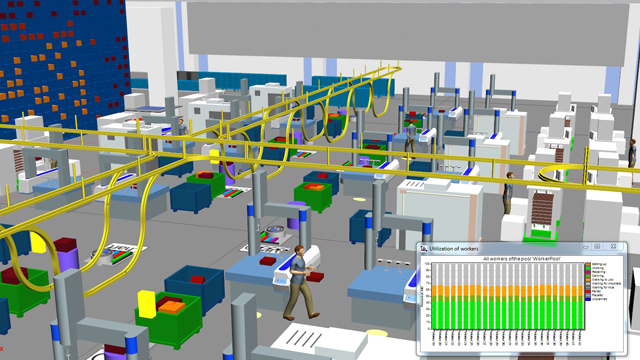

(21:20) “There’s one thing that few companies are using right now, which is the power of simulation. The power of simulating your whole factory, the power of simulating the way your machines interact, the powers of simulating how humans interact with machines. In terms of flows, in terms of quality, in terms of work orders, in terms of standard operating procedures. Up until now, it was quite labour intensive the use of machine learning algorithms to optimise that. If I have to do that manually every time I have a disruption, and disruption happens every day, then most probably I will not reshuffle my production, right? I will just leave it the way it it and I will just live with that disruption and say, okay, I accept these lower performance because of this disruption. If we have access to these simulation capabilities and the machine learning capabilities, we might not need to suffer those consequences, or at least so severely.”

Relevance

If you consider the factory as a manufacturing system, automation can help companies configure that manufacturing system so that it’s adjusted to respond to disruptions and it is operating at its optimum performance level.

Learn more

Vision

EIT Manufacturing vision for the future of Manufacturing in Europe in 2030, called ‘Fixing Our Future

Enablers

Enablers for future change and actions to make the vision, as described in Fixing Our Future, a reali

Signals

A knowledge library of over 100 signals of change, as examples of emerging manifestations towards the

About the project

Learn more about the background, the process and the people and the contributors behind this project.